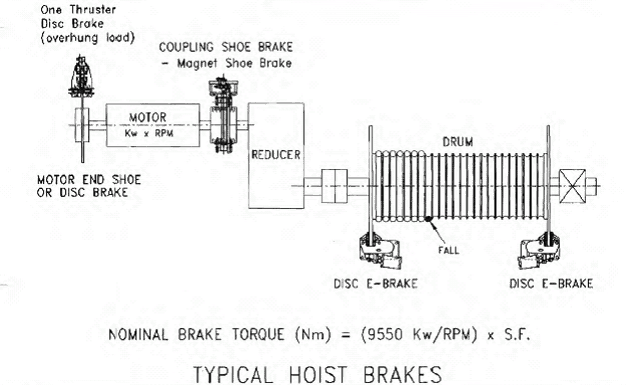

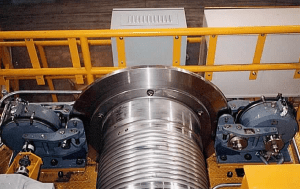

Crane Brake

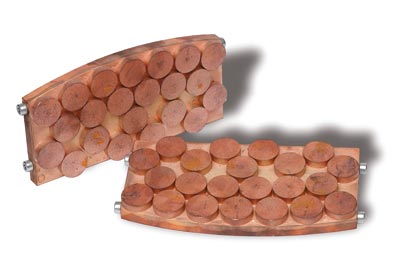

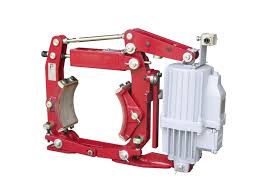

A typical braking system applies a (i.e. electromagnetic) force to apply friction, or mechanical resistance. This friction causes heat in its attempt to slow down and even stop a device in motion or to simply maintain it’s position without any motion.

Think of pressing your brake while driving your car. Your foot sends hydraulic brake fluid to a piston which in turn causes each brake pad to apply friction on your tires’ brake discs. The friction slows down each wheel and eventually stops your car.

Heavy Industry Brake, Clutch and Friction Systems

In heavy industry the brake, clutch and friction system is also used to slow and stop passenger or freight trains, wind turbines, cranes or hoists, etc. Even though there many types of brake system designs, their operation remains basically the same – to stop the movement.

When it comes to the selection of a heavy industrial brake, clutch and friction system it is imperative that one understands some key variables. These requisite and relevant variables are most critical to selecting the optimal product for your application.

I suggest there are three primary steps one should take in properly assessing an application.

- Recognizing and realizing the application and its fundamentals is the first step in the brake, clutch and friction selection process. To do so, you should identify the industry, application and specific parameters involved for the particular application. Is it a static or dynamic application? What is the operating environment like? (I.E. Is it hazardous?) What is the brake function and requirements? What is the system being used for?

- Now you must understand how to use this information and apply it to your specific application. In order to do this, one must fully understand exactly what these variables mean. You must comprehend such concepts as: static vs. dynamic; full motor and mechanical braking torque; friction coefficient as well as several others. These will be paramount when it comes to properly selecting a brake, clutch and friction material.

- Once you understand the variables and industry application specific aspects to your application it is time to apply these fundamentals and select your brake, clutch and friction material. You might consider collaborating with application engineers to perform a careful due diligence. This will ultimately lead to a better decision making process.

There are many brake and clutch manufacturers and many options to choose from. Our fast paced and price sensitive society has propelled business culture into often times rushing to decisions. This definitely has not necessarily helped industry as a whole.

At times the least expensive option is not the best alternative nor does the good old boy network work to your advantage. Take your time to investigate your alternatives.

This may help you make the best decision about a capital business expenditure. Ultimately in the long run it may prove to save your company a great deal of time and money.

Kor-Pak Corp. is an industrial brake and clutch specialist. Learn more about how Kor-Pak can help you resource your industrial brake, clutch and friction parts.

[button link=”/contact/” size=”large” bg_color=”red”]Kor-Pak Welcomes Unusual and Even Odd-Ball Requests (click to use our Contact form and test our response and attention!)[/button]

A February, 2016 report by Global Industry Analysts, Inc. (GIA) named GKN Stromag a key player in the industrial brakes and clutches market place. Amongst other highlights, the report forecasts a 40% growth in the global market for industrial automation equipment from 2013 to 2018. This in turn will likely set a very strong demand for industrial brakes and clutches.

A February, 2016 report by Global Industry Analysts, Inc. (GIA) named GKN Stromag a key player in the industrial brakes and clutches market place. Amongst other highlights, the report forecasts a 40% growth in the global market for industrial automation equipment from 2013 to 2018. This in turn will likely set a very strong demand for industrial brakes and clutches.

Kor-Pak is proud to announce that they are now ISO 9001:2008 certified which is another step that will take Kor-Pak to the next level as they are seeking aggressive growth strategies.

Kor-Pak is proud to announce that they are now ISO 9001:2008 certified which is another step that will take Kor-Pak to the next level as they are seeking aggressive growth strategies.