Hoist Crane Brakes, Hoist Disc Brakes, Crane Hoist Braking Systems

Hoist Crane Brakes, Hoist Disc Brakes, Crane Hoist Braking Systems for cranes are imperative for the safety and performance of your crane application. Whether it be a Ship-To-Shore Crane, Gantry Crane, Overhead Crane, or another crane type, Hoist

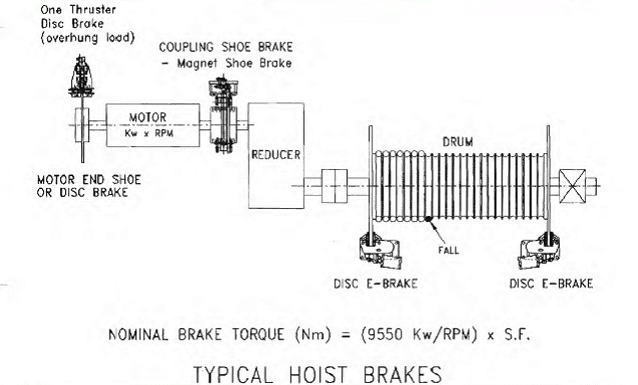

Hoist Brake Setup

Brakes are vital components of the industrial ecosystem that should be taken seriously and be properly specified and maintain.

To insure best practices for Hoist Brakes for Crane Application, it’s good to get back to the basics.

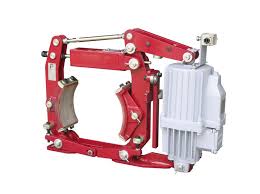

Hoist Brakes consist of shoe or disc brakes on the high speed side of the motor which are typically Thruster Disc Brakes, Thruster Drum Brakes, or Magnetic Drum Brakes. On the low speed side, it is important to have a Emergency Disc Brake system to prevent a load from falling in the event of a low-speed failure, such as gearbox or coupling failure or shaft breaking.

Specifying Hoist Crane Brakes, Hoist Disc Brakes, Crane Hoist Braking Systems

Low-speed brakes for hoist crane brakes applications are specified according to full motor torque plus a service factor. In the USA this is called out in AISE standards. The low-speed brakes are either used as dynamic stopping or static holding brakes, depending on whether there is a VFD controlling the motor as a primary brake. There are several variables that are involved when specifying these brakes such as:

- Environmental Factors (i.e. ambient temperature, dust/grime, saltwater exposure, etc.)

- Required torque

- Friction coefficient

- Duty Cycle

Thruster Disc Brake

Thruster Drum Brake

Magnetic Drum Brakes

- Controls Integration/PLC

- Several more

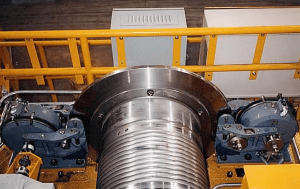

Emergency Disc Brakes

For the low-speed brakes, the brake(s) typically interface with a disc that is mounted on a flange on the drum. If this is not possible then the shaft can be extended or other alternatives are available. The emergency brake system is typically a caliper brake that is magnetic, hydraulic, or pneumatically released. An encoder can be mounted on the shaft that counts the pulses of the drum to measure the RPM and when a predetermined speed is reached, and “Overspeed Condition” is detected which triggers the E-Brakes to apply via a proportional controlled power unit so the brakes will not come to an “immediate stop” and the brakes will stop the load from falling without creating a “shock load.”

Magnetic Emergency Brakes

Hoist Crane Brakes, Hoist Disc Brakes, Crane Hoist Braking Systems

More detailed information regarding Crane Brakes, and specifically hoist brakes for cranes and emergency crane brake can be found in this Technical Paper. In this paper you will see that Europe has implemented strict standards on the requirement for emergency brakes for hot metal cranes and certain hoist applications, but this is still not a requirement in the USA. There have been numerous reported incidents of low-speed failures which have resulted in catastrophic failures that are extremely costly and some have caused fatalities. It is imperative that the USA adopts the same standards as Europe to create safer operating environments. While there is a cost to Emergency Crane Brake Systems, the benefits unequivocally exceed the costs when it comes to equipment protection, downtime, and most importantly, human lives.

Hoist Crane Brake Experts

Kor-Pak Corporation provides complete turkey systems for crane hoist brake systems including brakes, controls, installation, engineering, commissioning, and after-sales support. As subject matter experts, Kor-Pak will provide you with the quality, service, and engineering support you need to insure that your crane is operating as safely and efficiently as possible. For more information please contact a Kor-Pak representative today.