Description

DEMAG UNIVERSAL OVERHEAD CRANES

Our universal cranes drive quality, efficiency and reliability for your facility. Every crane and crane component reflects our vast engineering expertise and industry experience.

Our product portfolio includes single and double-girder overhead traveling cranes and suspension cranes. In addition to universal cranes with welded box-section girders, we offer solutions with rolled steel sections, wall-mounted traveling cranes, and crane sets.

Review product performance details and benefits on the product pages.

Demag V-Type Girder

The V-type crane revolutionizes load handling. Its innovative design featuring tapered diaphragm joints reduces oscillation frequency by 30%, cuts its weight by an average of 17% and doubles its service life to as many as 500,000 changes of load.

SINGLE GIRDER CRANES – OVERHEAD TRAVELING CRANE

Our EKKE single-girder overhead traveling cranes feature maximum rigidity and minimum deadweight. This maximizes crane runway loading and enables a more cost-effective building design and overall system solution.

High stability and design rigidity

- Torsionally rigid

- Optional rolled beam girder provides additional cost-savings

- Connections between the girder and end trucks are manufactured to precise machined tolerances for minimum wear

- End truck of torsionally rigid, welded box construction

- Excellent travel characteristics and minimum wear due to low-maintenance drives

- Travel wheels of highly wear-resistant GGG 70 spheroidal-graphite cast iron with self-lubricating properties

Highly cost-effective

- Low deadweight reduces cost – crane girders made of computer-optimized box sections

- Rope hoist helps reduce operating cost due to extended 2m+ service life classification (1,900 hours of service at full load)

- Reliable monitoring and preventive maintenance due to advanced CAN Bus technology

Efficiency and performance

- Control pendant suspended for separate travel on the crane girder

- Power supply to the trolley via high-flexibility flat cable with protective ground conductor

- Optional radio control with display and proportional pushbuttons

Modular design

- Contact us for additional options and customized system integration

Equipment Options

With our wide range of equipment options, we match our universal cranes to the individual requirements of your application:

- control by pendant switch

- control via interactive radio control with proportional pushbuttons

- end carriages with horizontal guide rollers to accomodate unique runway requirements.

- limit switches or slack rope relays protect the hoist and load from damage

- zone control system prevents collisions with obstacles along the trolley and bridge travel paths

- anti-collision protection and crane distance controls ensure the safe operation of several cranes on one runway

- cranes can be fitted with two trolleys with simultaneous/independent control for handling of long and non-standard loads

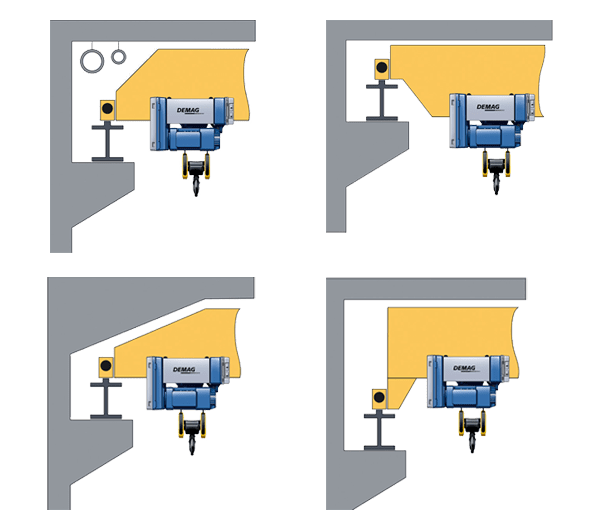

SUSPENSION CRANES – 10 TONS

Our EDKE suspension cranes are proven to maximize customer floospace and mobility. The cranes are typically attached to the existing roof structure – columns to support the crane runway are not needed. The installation of stand-alone steel superstructures also enable the solution to be flexible to production requirements.

High stability

- Rigid WF (wide flange) beam girders for optimum load distribution

- End carriages optimized for particular structure

Individual configuration

- Lateral overhangs to extend the cross-travel path beyond the runway span

- Flexible design enables sections of the workshop to be served

- Loads can be handled close to the building wall via customized girder overhand sections

- Equipped with DR rope hoist or DC chain hoist

- Optional latching devices enable trolley transfer from the crane girder to a monorail track

Modular design

- Contact us for additional options and customized system integration

ZKKE DOUBLE GIRDER OVERHEAD CRANES

Our double-girder overhead traveling cranes offer exceptional load capacity and minimum deadweight. Their precise and stable geometry provides travel characteristics that minimize wear on the end carriages and runway. In addition, the load hook can be raised between the two crane girders which enables maximum lifting heights.

High stability and design rigidity

- Torsionally rigid

- Connections between the girders and end trucks are manufactured to precise machined tolerances for minimum wear

- End truck of torsionally rigid, welded box construction

- Excellent travel characteristics and minimum wear due to low-maintenance drives

- Travel wheels of highly wear-resistant GGG 70 spheroidal-graphite cast iron with self-lubricating properties

Highly cost-effective

- Low deadweight reduces cost – crane girders made of computer-optimized box sections

- Rope hoist helps reduce operating cost due to extended 2m+ service life classification (1,900 hours of service at full load)

- Reliable monitoring and preventive maintenance due to advanced CAN Bus technology

Efficiency and performance

- Control pendant suspended for separate travel on the crane girder

- Power supply to the trolley via high-flexibility flat cable with protective ground conductor

- Optional radio control with display and proportional pushbuttons

Modular design

- Contact us for additional options and customized system integration

CRANE KITS

Our crane kits guarantee maximum quality, efficiency and reliability. They are based on standardized components for a wide variety of specific application configurations. Every component reflects our vast expertise with all aspects of crane design. Our crane kits feature:

- complete packages of components tailored to meet specific needs for single overhead traveling cranes

- single trolley operation

- Demag rope hoists to meet application requirements

- user-friendly assembly on the plug-&-play principle

- high safety, reliability and efficiency.

End carriages and travel units

- High rigidity

- Torsionally rigid, enclosed box-section profile (reinforced connection, welded diaphragm plate)

- Engineering tolerances in the crane girder connection area

- Optimum travel characteristics thanks to precise travel wheel axle arrangement and exact adjustment of the crane span dimension

- Low wear

- Maintenance-free travel drives thanks to anti-friction bearings lubricated for life and travel wheels made of spheroidal-graphite cast iron

Hoists

- High handling rates and efficiency

- Compact design

- Small approach dimensions

- Large hook path

- Optimum space utilization

- Low-sway transport and gentle positioning thanks to variable travel and lifting speeds

- Safety, reliability and convenient operation

Control system

- Ergonomically optimized control units

- Safe, fatigue-free handling

- Control pendant (suspended by cable for separate travel on the crane girder) or

- Optional radio control

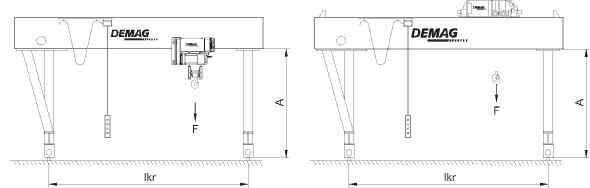

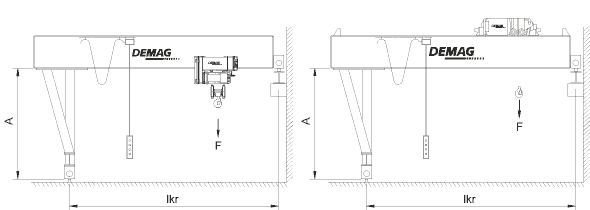

GANTRY CRANES – FULL GANTRY CRANES

Demag full-gantry cranes can be integrated into existing production facilities and inhouse logistics processes. The load-bearing crane girder is part of the frame structure which, together with the legs at either end, forms a traveling bridge. The cranes run on ground-level rails instead of elevated crane runways and power is supplied via a cable reel that is fitted to a leg. Full-gantry cranes are particularly effective for outdoor operation in storage yards and loading areas.

- Single-girder semi-gantry cranes: load capacities up to 12.5 tons, spans up to 98 ft.

- Double-girder semi-gantry cranes: load capacities up to 50 tons, spans up to 115 ft.

- Double-girder full-gantry cranes can include standard access ladder, maintenance walkway, and hoist trolley maintenance platform.

- Optional radio controls

- Can be equipped with 2 hoists or 2 trolleys

- Outdoor package with wind safety system to monitor outdoor operation

- Optional rail clamp that locks the crane to prevent damage in stormy conditions

Modular design

- Contact us for additional options and customized system integration

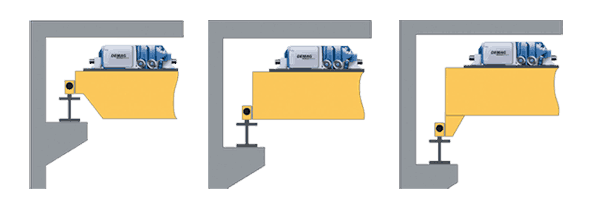

SEMI GANTRY CRANE

Our semi-gantry cranes are a cost-effective alternative wherever the installation of bridge cranes is impractical due to a need for a raised runway structure. They are also an ideal supplement to bridge cranes at the workstation level.

High operational value

- Efficient solution at workstation level

Cranes to meet specific customer needs

- Single-girder semi-gantry cranes with load capacities up to 12.5 tons (spans up to 98 ft.)

- Double-girder semi-gantry cranes with load capacities up to 50 tons (spans up to 115 ft.)

- Indoor or outdoor operation

- Controlled by pendant traveling station or optional radio controls

- Customized electric hoist configurations

Modular design

- Contact us for additional options and customized system integration