Products

-

Cojinetes y laminados fenólic (1)..

Cojinetes y laminados fenólicos Gatke (1)

-

Frenos contra tormentas y fren (1)..

Frenos contra tormentas y frenos de parada (1)

-

Frenos y embragues industriale (10)..

Frenos y embragues industriales (10)

-

Laminados fenólicos y Micarta (2)

Laminados fenólicos y Micarta (2)

-

Materiales de fricción para p (1)..

Materiales de fricción para papeleras (1)

-

Uncategorized (1000)

Uncategorized (1000)

-

Baldor AC Motors (2017)

Baldor AC Motors (2017)

-

Baldor DC Motor (95)

Baldor DC Motor (95)

-

Baldor Gearmotors (320)

Baldor Gearmotors (320)

-

Cranes and Hoists (18)

Cranes and Hoists (18)

Kor-Pak provides a complete line of Cranes and Hoists for various industrial applications, including: Overhead Cranes Gantry Cranes Ship-to-Shore Cranes Hoists End Trucks Spare Parts Mechanical, Electrical, and Hydraulic Crane Components Modernizations and Upgrades Repairs Crane Inspections Training 24/7 Support Contact Kor-Pak to assist you with your Crane and Hoist needs as we are an all-inclusive supplier and service provider.Kor-Pak provides a complete line of Cranes and Hoists for various industrial applications, including: Overhead Cranes Gantry Cranes Ship-to-Shore Cranes Hoists End Trucks Spare Parts Mechanical, Electrical, and Hydraulic Crane Components Modernizations and Upgrades Repairs Crane Inspections Training 24/7 Support Contact Kor-Pak to assist you with your Crane and Hoist needs as we are an all-inclusive supplier and service provider. -

Dellner Brakes (40)

Dellner Brakes (40)

-

Eaton Cutler Hammer Brakes &am (27)..

Eaton Cutler Hammer Brakes & Parts (27)

Cutler-Hammer Brakes & Parts Distributor

For a schematic an parts list click here. Kor-Pak is a leading distributor of Eaton Cutler-Hammer brakes and parts. You can contact us and we can help you determine the correct part number for your equipment, or you can browse our parts catalog and schematics.Cutler-Hammer Brake Rebuild

In addition to being a distributor of Cutler-Hammer brakes and parts, we also rebuild and recondition Eaton Cutler Hammer brakes. call us for an estimate on service or parts, or submit the form and we'll get back to you quickly.[caption id="attachment_3023" align="alignright" width="343"] Kor-Pak Rebuilt GH505 Brake with signature aluminum brake shoes[/caption]

[caption id="attachment_3022" align="alignnone" width="316"]

Kor-Pak Rebuilt GH505 Brake with signature aluminum brake shoes[/caption]

[caption id="attachment_3022" align="alignnone" width="316"] Cutler Hammer Brake Before Kor-Pak Recondition[/caption]

Cutler Hammer Brake Before Kor-Pak Recondition[/caption]

Benefits of Cutler Hammer GH505 Shoe Brakes

Cutler Hammer brakes are especially ideal since they have fewer moving parts than other DC Magnet brakes. This allows for fewer maintenance costs and an economical choice for reconditioning. Furthermore, it can fit well in tight spaces which can be ideal for certain applications. Cutler Hammer brakes can be used on both AC and DC cranes (need resistor for AC cranes). Gh505 brakes are offered with either shunt or series wound coils, and Kor-Pak offers both surplus and aftermarket options as well which can be more economical without compromising quality and performance. Kor-Pak has several GH505 DC brake assemblies and spare parts in stock; please peruse our website to see what we have in stock, and contact a Kor-Pak representative today with any questions.Cutler Hammer Brakes PublicationCutler Hammer Shunt Coil Info 8" Cutler Hammer GH505 Bulletin 23" Cutler Hammer GH505 Bulletin Kor-Pak DC Crane Controls Catalog8" GH505 Parts List

1 15-670 Nut KP0805001 2 16-1598 Spherical Washer KP0805002 3 69-2024 Spring KP0805003 4 13-3186-7 Spring Pin KP0805004 5 61-1013 Pull Rod KP0805005 6 969-482 Spring KP0805006 7 54-4020 Wedge Adjustment Assembly KP0805007 8 54-2863 Adjusting Wedge KP0805008 9 48-641-5 Armature (Inner) KP0805009 10 13-506-9 Pin KP0805010 11 48-641-6 Armature (Outer) KP0805011 12 73-1017 Rubber Guard KP0805012 13 13-3186-5 Spring Pin KP0805013 14 11-1746 Adjusting Screw Assembly KP0805014 15 49-2212 Gland KP0805015 16 69-1694 Compression Spring KP0805016 17 Coil 18 19-982-27 Lock Strip KP0805018 19 19-982-26 Lock Strip KP0805019 20 99-2058 Retro-fit Kit KP0805020 21 32-50-9 Felt KP0805021 22 24-3320-8 Shoe Lever (Inner) KP0805022 23 17-6371-2 Base KP0805023 25 55-1650 Retainer KP0805024 26 79-6783-5 Lock Bracket KP0805025 28 32-467 Dacron Felt KP0805026 29 24-3321-4 Shoe Lever (Outer) KP0805027 30 48-338-24 Shoe Lining KP0805028 31 55-1037 Clamp KP0805029 32 11-1788 Cap Screw KP0805030 33 69-1975 Lock Spring KP0805031 34 48-1267-4 Shoe KP0805032 10" GH505 Parts List

No. Part ID Description KP # 1 15-670 Nut KP0805001 2 16-1598 Spherical Washer KP0805002 3 69-2024 Spring KP0805003 4 13-3186-7 Spring Pin KP0805004 5 61-1006 Pull Rod KP1005005 6 69-290 Spring KP1005006 7 54-4020-2 Wedge Adjustment Assembly KP1005007 8 54-2813 Adjustment Wedge KP1005008 9 48-627-5 Armature (Inner) KP1005009 10 13-506-9 Pin (For Pull Rod) KP0805010 11 48-627-6 Armature (Outer) KP1005011 12 73-1017-2 Rubber Guard KP1005012 13 13-3186-5 Spring Pin KP0805013 14 11-1746-2 Adjustment Assembly KP1005014 15 49-2194-2 Gland KP1005015 16 69-1680 Compression Spring KP1005016 17 Coil 20 99-2058-2 Retro-Fit Kit KP1005018 21 32-50-8 Felt KP1005019 22 24-3288-9 Shoe Lever (Inner) KP1005020 23 17-6934 Base KP1005021 25 55-1650 Retainer KP0805024 26 79-6783-5 Lock Bracket KP0805025 27 55458 Screw KP1005024 28 32-467-2 Dacron Felt KP1005025 29 24-3289-4 Shoe Lever (Outer) KP1005026 30 48-338-22 Lining KP1005027 31 55-1037 Clamp KP0805029 32 11-1788 Cap Screw KP1005029 33 69-1975 Lock Spring KP0805031 34 48-1268-4 Shoe with Lining KP1005031 13" GH505 Parts List

No Part ID Description KP # 1 15-680 Locknut KP1305001 2 16-1598-2 Spherical Washer KP1305002 3 69-2029 Spring KP1305003 4 13-3186-7 Spring Pin KP0805004 5 61-985 Pull Rod KP1305005 6 69-942 Spring KP1305006 7 54-4020-7 Wedge Adjusting Assembly KP1305007 8 54-2652-2 Adjusting Wedge KP1305008 9 48-602-5 Armature (Inner) KP1305009 10 13-506-9 Pin (For Pull Rod) KP0805010 II 48-602-11 Armature (Outer) KP1305011 12 73-1017-3 Rubber Guard KP1305012 13 13-3186-9 Spring Pin KP1305013 14 11-1746-3 Adjusting Screw Assembly KP1305014 15 49-2153-2 Gland KP1305015 16 69-1652 Compression Spring KP1305016 17 Coil 18 19-982-20 Lock Strip KP1305018 19 19-982-19 Lock Strip KP1305019 20 99-2058-3 Retro-Fit Kit KP1305020 22 32-50-10 Felt KP1305021 23 24-3226-12 Shoe Lever (Inner) KP1305022 24 17-6934-2 Base KP1305023 26 55-1649 Retainer KP1305024 27 79-6783-5 Lock Bracket KP0805025 28 55458 Screw KP1005024 29 32-467-3 Dacron Felt KP1305027 30 24-3227-4 Shoe Lever (Outer) KP1305028 32 55-1037 Clamp KP0805029 33 11-1788 Screw KP0805030 34 69-1975 Lock Spring KP0805031 35 48-603-7 Shoe KP1305032 16" GH505 Parts List

No. Part ID Description KP # 1 15-681 Nut (Hug lock) KP1605001 2 16-1598-3 Spherical Washer KP1605002 3 69-2225 Compression Spring KP1605003 4 13-3186-7 Spring Pin KP0805004 5 61-912 Pull Rod KP1605005 6 69-942 Spring KP1305006 7 54-4020-8 Wedge Adjustment Assembly KP1605007 8 54-4524 Adjusting Wedge KP1605008 9 48-555-5 Armature (Inner) KP1605009 10 13-3978 Pin (For Pull Rod) KP1605010 11 48-555-6 Armature (Outer) KP1605011 12 73-1017-4 Rubber Guard KP1605012 13 13-3186-9 Spring Pin KP1305013 14 11-1746-4 Adjusting Screw Assembly KP1605014 15 49-2036 Gland KP1605015 16 69-1554 Compression Spring KP1605016 17 Coil 18 19-1164-2 Lock Strip KP1605018 19 19-1164 Lock Strip KP1605019 20 99-2059 Retro-Fit Kit KP1605020 21 19-972-8 Stop Block KP1605021 22 19-972-9 Stop Plate 093 Thick KP1605022 22 19-972-18 Stop Plate 105 Thick KP1605023 22 19-1688-5 Stop Plate 102 Thick KP1605024 23 32-50-11 Felt KP1605025 24 24-2951-9 Shoe Lever (Inner) KP1605026 25 17-8050 Base KP1605027 27 55458 Screw KP1005024 28 79-4180-27 Locking Bracket KP1605029 29 55-1551 Retainer KP1605030 30 32-467-4 Dacron Felt KP1605031 31 24-2950-3 Shoe Lever (Outer) KP1605032 32 48-338-12 Lining KP1605033 33 55-1079 Clamp KP1605034 34 11-1787 Cap Screw KP1605035 35 69-1976 Lock Spring KP1605036 36 48-554-3 Shoe KP1605037 19" GH505 Parts List

No. Part ID Description KP # 1 15-682 Nut (Hug lock) KP1905001 2 69-2226 Compression Spring KP1905002 3 13-3186-13 Spring Pin KP1905003 4 61-994-4 Pull Rod KP1905004 5 69-1470 Spring KP1905005 6 54-4020-4 Wedge Adjustment Assembly KP1905006 7 54-2764 Adjusting Wedge KP1905007 8 48-612-4 Armature (Inner) KP1905008 9 13-1181-11 Pin KP1905009 10 48-612-5 Armature (Outer) KP1905010 11 73-1017-5 Rubber Guard KP1905011 12 13-3186-12 Spring Pin KP1905012 13 11-1746-5 Adjusting Screw Assembly KP1905013 14 49-2172-2 Gland KP1905014 15 69-1664 Compression Spring KP1905015 16 Coil 17 19-982-24 Lock Strip KP1905017 18 19-982-23 Lock Strip KP1905018 19 99-2059-2 Retro-Fit Kit KP1905019 20 19-972-4 Stop Block KP1905020 21 19-972-16 Stop Plate 105 Thick KP1003034 21 19-1688-3 Stop Plate 102 Thick KP1905022 21 19-972-5 Stop Plate 093 Thick KP1905023 22 32-50-12 Felt KP1905024 23 24-3262-5 Shoe Lever (Inner) KP1905025 24 17-8050-2 Base KP1905026 26 55458 Screw KP1005024 27 79-4180-27 Locking Bracket KP1605029 28 55-1551 Retainer KP1605030 29 32-467-5 Dacron Felt KP1905030 30 24-3263-4 Shoe Lever (Outer) KP1905031 31 48-338-21 Shoe Lining KP1905032 32 55-1079 Clamp KP1605034 33 11-1787 Cap Screw KP1605035 34 69-1976 Lock Spring KP1605036 35 48-611 Shoe, Complete KP1905036 36 16-1598-4 Washer KP1905037 23" GH505 Parts

No. Part ID Description KP # 1 15-673 Nut (Hug lock) KP2305001 2 69-1987 Compression Spring KP2305002 3 13-3186-13 Spring Pin KP1905003 4 61-1008 Pull Rod KP2305004 5 69-1470 Spring KP1905005 6 54-4020-5 Wedge Adjustment Complete KP2305006 7 54-2764 Adjusting Wedge KP1905007 8 48-636-4 Armature (Inner) KP2305008 9 13-1181-16 Pin KP2305009 10 48-636-5 Armature (Outer) KP2305010 11 73-1017-6 Rubber Guard KP2305011 12 13-3186-12 Spring Pin KP1905012 13 11-1746-6 Adjusting Screw Complete KP2305013 14 49-2201-2 Gland KP2305014 15 69-1692 Compression Spring KP2305015 16 Coil 17 19-982-28 Locking Strip KP2305017 18 19-982-29 Locking Strip KP2305018 19 99-2059-3 Retro-Fit Kit KP2305019 20 19-972-6 Stop Block KP2305020 21 19-1688-4 Stop Plate 102 Thick KP2305021 21 19-972-7 Stop Plate 093 Thick KP2305022 21 19-972-17 Stop Plate 105 Thick KP2305023 22 32-50-13 Felt KP2305024 23 24-3304-5 Shoe Lever (Inner) KP2305025 24 17-8047 Base KP2305026 26 11-2051-2 Screw KP2305027 27 79-4180-28 Locking Bracket KP2305028 28 55-1548 Plate KP2305029 29 32-467-6 Dacron Felt KP2305030 30 24-3305-4 Shoe Lever (Outer) KP2305031 31 48-338-23 Shoe Lining KP2305032 32 55-1039 Clamp KP2305033 33 11-1786 Cap Screw KP1005029 34 69-1977 Lock Spring KP2305035 35 48-633-4 Shoe Complete KP2305036 36 16-1598-5 Washer KP2305037 30" Gh505 Parts

No. Part ID Description KP # 1 15-958 Hug lock Nut KP3005001 2 16-1981 Washer KP3005002 3 3228 Hex Head Screw KP3005003 3 15-610 Locknut KP3005004 4 69-2091 Compression Spring KP3005005 5 13-3186-21 Spring Pin KP3005006 6 61-1869 Pull Rod KP3005007 7 69-1931 Spring KP3005008 8 54-4020-6 Wedge Adjusting Screw KP3005009 9 54-4986 Adjusting Wedge KP3005010 10 48-896 Magnet Armature (Inner) KP3005011 11 27-82 Grease Fitting KP3005012 12 47-11498 Cover KP3005013 13 48-1260 Magnet Armature (Outer) KP3005014 14 13-5065 Pin KP3005015 14 18-1962 Stop Plate KP3005016 14 911-5888Z Screw KP3005017 15 345096 Adjusting Screw Assembly KP3005018 16 52-1079 Hook KP3005019 17 11-327 Hex Head Screw KP3005020 17 916-199 Lock washer KP3005021 18 69-2090 Compression Spring KP3005022 19 73-1210 Guard KP3005023 20 Coil 21 16-1747 Spring Plate KP3005025 22 14-527 Stud KP3005026 23 18-59-9 Shim KP3005027 23 18-59-5 Strap KP3005028 24 29-2779-5 Bushing KP3005029 25 24-4113 Inner Shoe Lever KP3005030 26 17-7102 Base KP3005031 27 48-338-25 Shoe Lining KP3005032 28 20-1067 Bearing Cap KP3005033 29 79-4180-18 Lock Bracket KP3005034 29 58746 Hex Head Screw KP3005035 31 59111 Hex Head Screw KP3005036 32 24-4112 Outer Shoe Lever KP3005037 33 48-830 Shoe Complete KP3005038 34 55-1352 Clamp KP3005039 35 69-2092 Locking Spring KP3005040 36 16-1982 Washer KP3005041 37 16-1983 Fabreeka Washer KP3005042 Cutler-Hammer Brakes & Parts Distributor

For a schematic an parts list click here. Kor-Pak is a leading distributor of Eaton Cutler-Hammer brakes and parts. You can contact us and we can help you determine the correct part number for your equipment, or you can browse our parts catalog and schematics.Cutler-Hammer Brake Rebuild

In addition to being a distributor of Cutler-Hammer brakes and parts, we also rebuild and recondition Eaton Cutler Hammer brakes. call us for an estimate on service or parts, or submit the form and we'll get back to you quickly.[caption id="attachment_3023" align="alignright" width="343"] Kor-Pak Rebuilt GH505 Brake with signature aluminum brake shoes[/caption][caption id="attachment_3022" align="alignnone" width="316"] Cutler Hammer Brake Before Kor-Pak Recondition[/caption]Benefits of Cutler Hammer GH505 Shoe Brakes

Cutler Hammer brakes are especially ideal since they have fewer moving parts than other DC Magnet brakes. This allows for fewer maintenance costs and an economical choice for reconditioning. Furthermore, it can fit well in tight spaces which can be ideal for certain applications. Cutler Hammer brakes can be used on both AC and DC cranes (need resistor for AC cranes). Gh505 brakes are offered with either shunt or series wound coils, and Kor-Pak offers both surplus and aftermarket options as well which can be more economical without compromising quality and performance. Kor-Pak has several GH505 DC brake assemblies and spare parts in stock; please peruse our website to see what we have in stock, and contact a Kor-Pak representative today with any questions.Cutler Hammer Brakes PublicationCutler Hammer Shunt Coil Info 8" Cutler Hammer GH505 Bulletin 23" Cutler Hammer GH505 Bulletin Kor-Pak DC Crane Controls Catalog8" GH505 Parts List

1 15-670 Nut KP0805001 2 16-1598 Spherical Washer KP0805002 3 69-2024 Spring KP0805003 4 13-3186-7 Spring Pin KP0805004 5 61-1013 Pull Rod KP0805005 6 969-482 Spring KP0805006 7 54-4020 Wedge Adjustment Assembly KP0805007 8 54-2863 Adjusting Wedge KP0805008 9 48-641-5 Armature (Inner) KP0805009 10 13-506-9 Pin KP0805010 11 48-641-6 Armature (Outer) KP0805011 12 73-1017 Rubber Guard KP0805012 13 13-3186-5 Spring Pin KP0805013 14 11-1746 Adjusting Screw Assembly KP0805014 15 49-2212 Gland KP0805015 16 69-1694 Compression Spring KP0805016 17 Coil 18 19-982-27 Lock Strip KP0805018 19 19-982-26 Lock Strip KP0805019 20 99-2058 Retro-fit Kit KP0805020 21 32-50-9 Felt KP0805021 22 24-3320-8 Shoe Lever (Inner) KP0805022 23 17-6371-2 Base KP0805023 25 55-1650 Retainer KP0805024 26 79-6783-5 Lock Bracket KP0805025 28 32-467 Dacron Felt KP0805026 29 24-3321-4 Shoe Lever (Outer) KP0805027 30 48-338-24 Shoe Lining KP0805028 31 55-1037 Clamp KP0805029 32 11-1788 Cap Screw KP0805030 33 69-1975 Lock Spring KP0805031 34 48-1267-4 Shoe KP0805032 10" GH505 Parts List

No. Part ID Description KP # 1 15-670 Nut KP0805001 2 16-1598 Spherical Washer KP0805002 3 69-2024 Spring KP0805003 4 13-3186-7 Spring Pin KP0805004 5 61-1006 Pull Rod KP1005005 6 69-290 Spring KP1005006 7 54-4020-2 Wedge Adjustment Assembly KP1005007 8 54-2813 Adjustment Wedge KP1005008 9 48-627-5 Armature (Inner) KP1005009 10 13-506-9 Pin (For Pull Rod) KP0805010 11 48-627-6 Armature (Outer) KP1005011 12 73-1017-2 Rubber Guard KP1005012 13 13-3186-5 Spring Pin KP0805013 14 11-1746-2 Adjustment Assembly KP1005014 15 49-2194-2 Gland KP1005015 16 69-1680 Compression Spring KP1005016 17 Coil 20 99-2058-2 Retro-Fit Kit KP1005018 21 32-50-8 Felt KP1005019 22 24-3288-9 Shoe Lever (Inner) KP1005020 23 17-6934 Base KP1005021 25 55-1650 Retainer KP0805024 26 79-6783-5 Lock Bracket KP0805025 27 55458 Screw KP1005024 28 32-467-2 Dacron Felt KP1005025 29 24-3289-4 Shoe Lever (Outer) KP1005026 30 48-338-22 Lining KP1005027 31 55-1037 Clamp KP0805029 32 11-1788 Cap Screw KP1005029 33 69-1975 Lock Spring KP0805031 34 48-1268-4 Shoe with Lining KP1005031 13" GH505 Parts List

No Part ID Description KP # 1 15-680 Locknut KP1305001 2 16-1598-2 Spherical Washer KP1305002 3 69-2029 Spring KP1305003 4 13-3186-7 Spring Pin KP0805004 5 61-985 Pull Rod KP1305005 6 69-942 Spring KP1305006 7 54-4020-7 Wedge Adjusting Assembly KP1305007 8 54-2652-2 Adjusting Wedge KP1305008 9 48-602-5 Armature (Inner) KP1305009 10 13-506-9 Pin (For Pull Rod) KP0805010 II 48-602-11 Armature (Outer) KP1305011 12 73-1017-3 Rubber Guard KP1305012 13 13-3186-9 Spring Pin KP1305013 14 11-1746-3 Adjusting Screw Assembly KP1305014 15 49-2153-2 Gland KP1305015 16 69-1652 Compression Spring KP1305016 17 Coil 18 19-982-20 Lock Strip KP1305018 19 19-982-19 Lock Strip KP1305019 20 99-2058-3 Retro-Fit Kit KP1305020 22 32-50-10 Felt KP1305021 23 24-3226-12 Shoe Lever (Inner) KP1305022 24 17-6934-2 Base KP1305023 26 55-1649 Retainer KP1305024 27 79-6783-5 Lock Bracket KP0805025 28 55458 Screw KP1005024 29 32-467-3 Dacron Felt KP1305027 30 24-3227-4 Shoe Lever (Outer) KP1305028 32 55-1037 Clamp KP0805029 33 11-1788 Screw KP0805030 34 69-1975 Lock Spring KP0805031 35 48-603-7 Shoe KP1305032 16" GH505 Parts List

No. Part ID Description KP # 1 15-681 Nut (Hug lock) KP1605001 2 16-1598-3 Spherical Washer KP1605002 3 69-2225 Compression Spring KP1605003 4 13-3186-7 Spring Pin KP0805004 5 61-912 Pull Rod KP1605005 6 69-942 Spring KP1305006 7 54-4020-8 Wedge Adjustment Assembly KP1605007 8 54-4524 Adjusting Wedge KP1605008 9 48-555-5 Armature (Inner) KP1605009 10 13-3978 Pin (For Pull Rod) KP1605010 11 48-555-6 Armature (Outer) KP1605011 12 73-1017-4 Rubber Guard KP1605012 13 13-3186-9 Spring Pin KP1305013 14 11-1746-4 Adjusting Screw Assembly KP1605014 15 49-2036 Gland KP1605015 16 69-1554 Compression Spring KP1605016 17 Coil 18 19-1164-2 Lock Strip KP1605018 19 19-1164 Lock Strip KP1605019 20 99-2059 Retro-Fit Kit KP1605020 21 19-972-8 Stop Block KP1605021 22 19-972-9 Stop Plate 093 Thick KP1605022 22 19-972-18 Stop Plate 105 Thick KP1605023 22 19-1688-5 Stop Plate 102 Thick KP1605024 23 32-50-11 Felt KP1605025 24 24-2951-9 Shoe Lever (Inner) KP1605026 25 17-8050 Base KP1605027 27 55458 Screw KP1005024 28 79-4180-27 Locking Bracket KP1605029 29 55-1551 Retainer KP1605030 30 32-467-4 Dacron Felt KP1605031 31 24-2950-3 Shoe Lever (Outer) KP1605032 32 48-338-12 Lining KP1605033 33 55-1079 Clamp KP1605034 34 11-1787 Cap Screw KP1605035 35 69-1976 Lock Spring KP1605036 36 48-554-3 Shoe KP1605037 19" GH505 Parts List

No. Part ID Description KP # 1 15-682 Nut (Hug lock) KP1905001 2 69-2226 Compression Spring KP1905002 3 13-3186-13 Spring Pin KP1905003 4 61-994-4 Pull Rod KP1905004 5 69-1470 Spring KP1905005 6 54-4020-4 Wedge Adjustment Assembly KP1905006 7 54-2764 Adjusting Wedge KP1905007 8 48-612-4 Armature (Inner) KP1905008 9 13-1181-11 Pin KP1905009 10 48-612-5 Armature (Outer) KP1905010 11 73-1017-5 Rubber Guard KP1905011 12 13-3186-12 Spring Pin KP1905012 13 11-1746-5 Adjusting Screw Assembly KP1905013 14 49-2172-2 Gland KP1905014 15 69-1664 Compression Spring KP1905015 16 Coil 17 19-982-24 Lock Strip KP1905017 18 19-982-23 Lock Strip KP1905018 19 99-2059-2 Retro-Fit Kit KP1905019 20 19-972-4 Stop Block KP1905020 21 19-972-16 Stop Plate 105 Thick KP1003034 21 19-1688-3 Stop Plate 102 Thick KP1905022 21 19-972-5 Stop Plate 093 Thick KP1905023 22 32-50-12 Felt KP1905024 23 24-3262-5 Shoe Lever (Inner) KP1905025 24 17-8050-2 Base KP1905026 26 55458 Screw KP1005024 27 79-4180-27 Locking Bracket KP1605029 28 55-1551 Retainer KP1605030 29 32-467-5 Dacron Felt KP1905030 30 24-3263-4 Shoe Lever (Outer) KP1905031 31 48-338-21 Shoe Lining KP1905032 32 55-1079 Clamp KP1605034 33 11-1787 Cap Screw KP1605035 34 69-1976 Lock Spring KP1605036 35 48-611 Shoe, Complete KP1905036 36 16-1598-4 Washer KP1905037 23" GH505 Parts

No. Part ID Description KP # 1 15-673 Nut (Hug lock) KP2305001 2 69-1987 Compression Spring KP2305002 3 13-3186-13 Spring Pin KP1905003 4 61-1008 Pull Rod KP2305004 5 69-1470 Spring KP1905005 6 54-4020-5 Wedge Adjustment Complete KP2305006 7 54-2764 Adjusting Wedge KP1905007 8 48-636-4 Armature (Inner) KP2305008 9 13-1181-16 Pin KP2305009 10 48-636-5 Armature (Outer) KP2305010 11 73-1017-6 Rubber Guard KP2305011 12 13-3186-12 Spring Pin KP1905012 13 11-1746-6 Adjusting Screw Complete KP2305013 14 49-2201-2 Gland KP2305014 15 69-1692 Compression Spring KP2305015 16 Coil 17 19-982-28 Locking Strip KP2305017 18 19-982-29 Locking Strip KP2305018 19 99-2059-3 Retro-Fit Kit KP2305019 20 19-972-6 Stop Block KP2305020 21 19-1688-4 Stop Plate 102 Thick KP2305021 21 19-972-7 Stop Plate 093 Thick KP2305022 21 19-972-17 Stop Plate 105 Thick KP2305023 22 32-50-13 Felt KP2305024 23 24-3304-5 Shoe Lever (Inner) KP2305025 24 17-8047 Base KP2305026 26 11-2051-2 Screw KP2305027 27 79-4180-28 Locking Bracket KP2305028 28 55-1548 Plate KP2305029 29 32-467-6 Dacron Felt KP2305030 30 24-3305-4 Shoe Lever (Outer) KP2305031 31 48-338-23 Shoe Lining KP2305032 32 55-1039 Clamp KP2305033 33 11-1786 Cap Screw KP1005029 34 69-1977 Lock Spring KP2305035 35 48-633-4 Shoe Complete KP2305036 36 16-1598-5 Washer KP2305037 30" Gh505 Parts

No. Part ID Description KP # 1 15-958 Hug lock Nut KP3005001 2 16-1981 Washer KP3005002 3 3228 Hex Head Screw KP3005003 3 15-610 Locknut KP3005004 4 69-2091 Compression Spring KP3005005 5 13-3186-21 Spring Pin KP3005006 6 61-1869 Pull Rod KP3005007 7 69-1931 Spring KP3005008 8 54-4020-6 Wedge Adjusting Screw KP3005009 9 54-4986 Adjusting Wedge KP3005010 10 48-896 Magnet Armature (Inner) KP3005011 11 27-82 Grease Fitting KP3005012 12 47-11498 Cover KP3005013 13 48-1260 Magnet Armature (Outer) KP3005014 14 13-5065 Pin KP3005015 14 18-1962 Stop Plate KP3005016 14 911-5888Z Screw KP3005017 15 345096 Adjusting Screw Assembly KP3005018 16 52-1079 Hook KP3005019 17 11-327 Hex Head Screw KP3005020 17 916-199 Lock washer KP3005021 18 69-2090 Compression Spring KP3005022 19 73-1210 Guard KP3005023 20 Coil 21 16-1747 Spring Plate KP3005025 22 14-527 Stud KP3005026 23 18-59-9 Shim KP3005027 23 18-59-5 Strap KP3005028 24 29-2779-5 Bushing KP3005029 25 24-4113 Inner Shoe Lever KP3005030 26 17-7102 Base KP3005031 27 48-338-25 Shoe Lining KP3005032 28 20-1067 Bearing Cap KP3005033 29 79-4180-18 Lock Bracket KP3005034 29 58746 Hex Head Screw KP3005035 31 59111 Hex Head Screw KP3005036 32 24-4112 Outer Shoe Lever KP3005037 33 48-830 Shoe Complete KP3005038 34 55-1352 Clamp KP3005039 35 69-2092 Locking Spring KP3005040 36 16-1982 Washer KP3005041 37 16-1983 Fabreeka Washer KP3005042 Cutler Hammer Brakes Publication Cutler Hammer Shunt Coil Info 8" Cutler Hammer GH505 Bulletin 23" Cutler Hammer GH505 Bulletin GH505 Brakes

EC&M Square D Brakes (7)

EC&M Square D Brakes (7)

Square D Brakes & parts

Square D brakes & brake parts from Kor-Pak. Contact us with your specs/application needs, and we will ensure you have the correct products.\Square D Brakes & parts

Square D brakes & brake parts from Kor-Pak. Contact us with your specs/application needs, and we will ensure you have the correct products.\

Galvi Brakes (62)

Galvi Brakes (62)

Gleason Parts (4196)

Gleason Parts (4196)

HUAWU Brakes (61)

HUAWU Brakes (61)

Johnson Brakes (319)

Johnson Brakes (319)

Kobelt Brakes (12)

Kobelt Brakes (12)

Magnetek AC Motor Control (3180)

Magnetek AC Motor Control (3180)

Marine Bearings (1)

Marine Bearings (1)

Kor-Pak provides a variety of Impregnated Phenolic Bearings for Marine Applications. For instance, Kor-Pak Rudder Bearings are self-lubricating and function extremely well without grease above and below the waterline and possesses extremely high impact strength and can endure harsh shock loads and provide outstanding friction characteristics which allows them to far outlast metal and other alternatives. Try Kor-Pak bearings to see how they truly make the difference. For More Information about Kor-Pak Marine bearings, CONTACT a Kor-Pak representative today.Kor-Pak provides a variety of Impregnated Phenolic Bearings for Marine Applications. For instance, Kor-Pak Rudder Bearings are self-lubricating and function extremely well without grease above and below the waterline and possesses extremely high impact strength and can endure harsh shock loads and provide outstanding friction characteristics which allows them to far outlast metal and other alternatives. Try Kor-Pak bearings to see how they truly make the difference. For More Information about Kor-Pak Marine bearings, CONTACT a Kor-Pak representative today.

Micarta and Phenolic Laminates (8)

Micarta and Phenolic Laminates (8)

Kor-Pak is a Phenolic specialist, carrying various grades of phenolic materials to accommodate numerous applications. Common brand names that we carry include: Micarta

Ryertex

Gatke

Canvas Phenolic

What are Phenolics, and what are their applications?

Micarta became a brand name when it was developed by George Westinghouse in the early 1900's using phenolic resins. Micarta is now used as the general brand name term for resin impregnated fibre compounds. This material is made from phenolic resins used to impregnate paper and cotton fabric which are cured under pressure and high temperatures to produce laminates.

Micarta industrial laminates are typically phenolic, epoxy, silicon-based thermoset materials reinforced with fiberglass, cotton, cloth, paper, carbon fiber, moly, teflon, and others. Pressure and heat is applied to layers of laminations which yields a chemical reaction (polymerization) which turns the layers into high-pressure thermosetting industrial laminated plastic. There are numerous commercial grades which industrial laminates are manufactured in.

Where are Micarta/Phenolic Laminates used?

Micarta

Ryertex

Gatke

Canvas Phenolic

What are Phenolics, and what are their applications?

Micarta became a brand name when it was developed by George Westinghouse in the early 1900's using phenolic resins. Micarta is now used as the general brand name term for resin impregnated fibre compounds. This material is made from phenolic resins used to impregnate paper and cotton fabric which are cured under pressure and high temperatures to produce laminates.

Micarta industrial laminates are typically phenolic, epoxy, silicon-based thermoset materials reinforced with fiberglass, cotton, cloth, paper, carbon fiber, moly, teflon, and others. Pressure and heat is applied to layers of laminations which yields a chemical reaction (polymerization) which turns the layers into high-pressure thermosetting industrial laminated plastic. There are numerous commercial grades which industrial laminates are manufactured in.

Where are Micarta/Phenolic Laminates used? The most popular application for Micarta/Phenolic Laminates is in high strength electrical insulation. Micarta/Phenolic Laminates are used in power generating and distribution equipment, aerospace, electronic, marine, heavy equipment, steel, paper, and various other industries/applications.

The most popular application for Micarta/Phenolic Laminates is in high strength electrical insulation. Micarta/Phenolic Laminates are used in power generating and distribution equipment, aerospace, electronic, marine, heavy equipment, steel, paper, and various other industries/applications.

Kor-Pak Corporation provides several grades of Micarta/Phenolic Laminates and can perform machining, grinding, shearing, sanding, and sawing services to furnish you with the exact product you need. Sheets of material are also available in different grades and dimensions. Please contact a Kor-Pak representative for more information and price/availability. Kor-Pak Phenolic Laminate products typically ship from stock and custom orders will have short lead times. We offer: Rods 1/32" to 6" diameter lengths up to 6"- Terminal Boards

- Casings

- Antenna Insulators

- Printed Circuit Boards

- Stand Offs • Washers

- Spacers

- PC Board Insulator

- Switch Gears

- FR4 PCB

- Board

- Sheets

- Plates

- Rods

- Phenolic

- G10 Tubing

- G10 Plastics

- G10 Composites

- PCB Materials

- Black G10

- Machining

- Fiberglass

- Panels

- Nema Grade

- Circuit Board Material

- Copper Clad

- Industrial Tubes

Sheets

.004" through 6" thick sizes up to 48" X 96"

Tubes

Custom made to your desired specifications

Machining

Precision machining available to accommodate challenging tolerances and requirements

Related Materials

Ryertex Line CardKor-Pak is a Phenolic specialist, carrying various grades of phenolic materials to accommodate numerous applications. Common brand names that we carry include: Micarta Ryertex Gatke Canvas Phenolic What are Phenolics, and what are their applications? Micarta became a brand name when it was developed by George Westinghouse in the early 1900's using phenolic resins. Micarta is now used as the general brand name term for resin impregnated fibre compounds. This material is made from phenolic resins used to impregnate paper and cotton fabric which are cured under pressure and high temperatures to produce laminates. Micarta industrial laminates are typically phenolic, epoxy, silicon-based thermoset materials reinforced with fiberglass, cotton, cloth, paper, carbon fiber, moly, teflon, and others. Pressure and heat is applied to layers of laminations which yields a chemical reaction (polymerization) which turns the layers into high-pressure thermosetting industrial laminated plastic. There are numerous commercial grades which industrial laminates are manufactured in. Where are Micarta/Phenolic Laminates used? The most popular application for Micarta/Phenolic Laminates is in high strength electrical insulation. Micarta/Phenolic Laminates are used in power generating and distribution equipment, aerospace, electronic, marine, heavy equipment, steel, paper, and various other industries/applications.

Sheets

.004" through 6" thick sizes up to 48" X 96"

Tubes

Custom made to your desired specifications

Machining

Precision machining available to accommodate challenging tolerances and requirements

Related Materials

Ryertex Line CardKor-Pak is a Phenolic specialist, carrying various grades of phenolic materials to accommodate numerous applications. Common brand names that we carry include: Micarta Ryertex Gatke Canvas Phenolic What are Phenolics, and what are their applications? Micarta became a brand name when it was developed by George Westinghouse in the early 1900's using phenolic resins. Micarta is now used as the general brand name term for resin impregnated fibre compounds. This material is made from phenolic resins used to impregnate paper and cotton fabric which are cured under pressure and high temperatures to produce laminates. Micarta industrial laminates are typically phenolic, epoxy, silicon-based thermoset materials reinforced with fiberglass, cotton, cloth, paper, carbon fiber, moly, teflon, and others. Pressure and heat is applied to layers of laminations which yields a chemical reaction (polymerization) which turns the layers into high-pressure thermosetting industrial laminated plastic. There are numerous commercial grades which industrial laminates are manufactured in. Where are Micarta/Phenolic Laminates used? The most popular application for Micarta/Phenolic Laminates is in high strength electrical insulation. Micarta/Phenolic Laminates are used in power generating and distribution equipment, aerospace, electronic, marine, heavy equipment, steel, paper, and various other industries/applications.

Kor-Pak Corporation provides several grades of Micarta/Phenolic Laminates and can perform machining, grinding, shearing, sanding, and sawing services to furnish you with the exact product you need. Sheets of material are also available in different grades and dimensions. Please contact a Kor-Pak representative for more information and price/availability. Kor-Pak Phenolic Laminate products typically ship from stock and custom orders will have short lead times. We offer: Rods 1/32" to 6" diameter lengths up to 6" Sheets .004" through 6" thick sizes up to 48" X 96" Tubes Custom made to your desired specifications Machining Precision machining available to accommodate challenging tolerances and requirements Related Materials Ryertex Line Card- Terminal Boards

- Casings

- Antenna Insulators

- Printed Circuit Boards

- Stand Offs • Washers

- Spacers

- PC Board Insulator

- Switch Gears

- FR4 PCB

- Board

- Sheets

- Plates

- Rods

- Phenolic

- G10 Tubing

- G10 Plastics

- G10 Composites

- PCB Materials

- Black G10

- Machining

- Fiberglass

- Panels

- Nema Grade

- Circuit Board Material

- Copper Clad

- Industrial Tubes

Mondel - Magnetek Brakes & (3)..

Mondel - Magnetek Brakes & Motors (3)

Magnetek Distributor

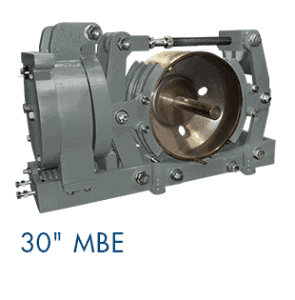

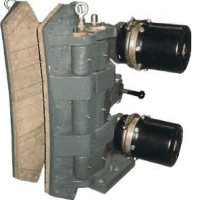

Kor-Pak is an authorized dealer/distributor for Mondel Brakes, a subsidiary of Magnetek Uncommon Power in Menomonee Falls, WI. Mondel Brakes are robust, versatile, and capable of withstanding harsh environments which is why they are a top choice for tough environments such as melt shop cranes and stacker reclaimers. Mondel Brakes are offered in various styles including the acclaimed MBE DC Magnetic Drum Brakes and MBT Thruster Show Brakes. More information on these brakes can be found below:

Type "MBE" - DC Magnet

[caption id="attachment_2115" align="alignright" width="295"]

Kor-Pak is an authorized dealer/distributor for Mondel Brakes, a subsidiary of Magnetek Uncommon Power in Menomonee Falls, WI. Mondel Brakes are robust, versatile, and capable of withstanding harsh environments which is why they are a top choice for tough environments such as melt shop cranes and stacker reclaimers. Mondel Brakes are offered in various styles including the acclaimed MBE DC Magnetic Drum Brakes and MBT Thruster Show Brakes. More information on these brakes can be found below:

Type "MBE" - DC Magnet

[caption id="attachment_2115" align="alignright" width="295"] 30" Mondel MBE DC Magnet Brake[/caption]

Spring –applied and electromagnetic release

Replaceable magnet coils

Class F insulation

Shunt: 12V through 350V DC

Series: 5A through 1400A

300M Range

5” – 30” diameter

10 – 11,000 lb. ft. torque

AC, DC, hydraulic

Explosion proof

AIST drop-in designs

MBE Options:

Auto-adjuster for lining wear

Forcing rectifier (fast response for crane hoists, etc.)

Constant potential rectifiers (for crane bridges/trolleys)

Terminal box rectifiers (Special applications - Contact Engineering)

Class H insulation

Nitride Corrosion Protection

Type "MBT" - 3 PH. AC and DC

30" Mondel MBE DC Magnet Brake[/caption]

Spring –applied and electromagnetic release

Replaceable magnet coils

Class F insulation

Shunt: 12V through 350V DC

Series: 5A through 1400A

300M Range

5” – 30” diameter

10 – 11,000 lb. ft. torque

AC, DC, hydraulic

Explosion proof

AIST drop-in designs

MBE Options:

Auto-adjuster for lining wear

Forcing rectifier (fast response for crane hoists, etc.)

Constant potential rectifiers (for crane bridges/trolleys)

Terminal box rectifiers (Special applications - Contact Engineering)

Class H insulation

Nitride Corrosion Protection

Type "MBT" - 3 PH. AC and DC Fast response - standard units 2000 cycles per hour

Spring applied and electrically released

Continuously or intermittently rated, Service < 40°C

Class F insulation

AC Supplies: 230-460-575/3Ph/50-60 Hz

DC Supplies: 250V

MBT Options:

Auto-adjuster for lining wear

Adjustable external torque spring with calibrated indicator

Externally adjustable, stepless time delays in both directions (set and release)

Braketronic Controller

Nitride Corrosion Protection

[caption id="attachment_2114" align="alignright" width="150"]

Fast response - standard units 2000 cycles per hour

Spring applied and electrically released

Continuously or intermittently rated, Service < 40°C

Class F insulation

AC Supplies: 230-460-575/3Ph/50-60 Hz

DC Supplies: 250V

MBT Options:

Auto-adjuster for lining wear

Adjustable external torque spring with calibrated indicator

Externally adjustable, stepless time delays in both directions (set and release)

Braketronic Controller

Nitride Corrosion Protection

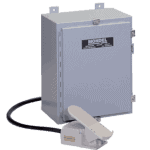

[caption id="attachment_2114" align="alignright" width="150"] Mondel "Braketronic" Controller[/caption]

Latching hand release

Up to 3 limit switches to indicate brake position

Available in vertical design

– Thruster is mounted above the brakewheel

– Fits in tight spaces

Types "MBT" and "MBE can be fitted with Pedal or

Mondel "Braketronic" Controller

Power assisted hydraulic over-ride to produce a dual-purpose brake. This hybrid brake is useful for EOT bridges, gantry cranes and similar applications where dual control and/or emergency stopping and parking are required.

Related Literature:

Mondel Family Brochure

Brakes for Cranes and Hoists

Mondel "Braketronic" Controller[/caption]

Latching hand release

Up to 3 limit switches to indicate brake position

Available in vertical design

– Thruster is mounted above the brakewheel

– Fits in tight spaces

Types "MBT" and "MBE can be fitted with Pedal or

Mondel "Braketronic" Controller

Power assisted hydraulic over-ride to produce a dual-purpose brake. This hybrid brake is useful for EOT bridges, gantry cranes and similar applications where dual control and/or emergency stopping and parking are required.

Related Literature:

Mondel Family Brochure

Brakes for Cranes and HoistsMagnetek Distributor

Kor-Pak is an authorized dealer/distributor for Mondel Brakes, a subsidiary of Magnetek Uncommon Power in Menomonee Falls, WI. Mondel Brakes are robust, versatile, and capable of withstanding harsh environments which is why they are a top choice for tough environments such as melt shop cranes and stacker reclaimers. Mondel Brakes are offered in various styles including the acclaimed MBE DC Magnetic Drum Brakes and MBT Thruster Show Brakes. More information on these brakes can be found below: Type "MBE" - DC Magnet [caption id="attachment_2115" align="alignright" width="295"] 30" Mondel MBE DC Magnet Brake[/caption] Spring –applied and electromagnetic release Replaceable magnet coils Class F insulation Shunt: 12V through 350V DC Series: 5A through 1400A 300M Range 5” – 30” diameter 10 – 11,000 lb. ft. torque AC, DC, hydraulic Explosion proof AIST drop-in designs MBE Options: Auto-adjuster for lining wear Forcing rectifier (fast response for crane hoists, etc.) Constant potential rectifiers (for crane bridges/trolleys) Terminal box rectifiers (Special applications - Contact Engineering) Class H insulation Nitride Corrosion Protection Type "MBT" - 3 PH. AC and DC Fast response - standard units 2000 cycles per hour Spring applied and electrically released Continuously or intermittently rated, Service < 40°C Class F insulation AC Supplies: 230-460-575/3Ph/50-60 Hz DC Supplies: 250V MBT Options: Auto-adjuster for lining wear Adjustable external torque spring with calibrated indicator Externally adjustable, stepless time delays in both directions (set and release) Braketronic Controller Nitride Corrosion Protection [caption id="attachment_2114" align="alignright" width="150"] Mondel "Braketronic" Controller[/caption] Latching hand release Up to 3 limit switches to indicate brake position Available in vertical design – Thruster is mounted above the brakewheel – Fits in tight spaces Types "MBT" and "MBE can be fitted with Pedal or Mondel "Braketronic" Controller Power assisted hydraulic over-ride to produce a dual-purpose brake. This hybrid brake is useful for EOT bridges, gantry cranes and similar applications where dual control and/or emergency stopping and parking are required. Related Literature: Mondel Family Brochure Brakes for Cranes and Hoists

Mondel Brakes (39)

Mondel Brakes (39)

Oil Rig Equipment (6)

Oil Rig Equipment (6)

Kor-Pak is your premier source for Oil Rig Equipment

Kor-Pak is a manufacturer and distributor for various Oil Rig products, including:

Kor-Pak is your premier source for Oil Rig Equipment

Kor-Pak is a manufacturer and distributor for various Oil Rig products, including:

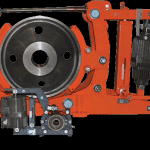

Brakes, Clutches, and Accessories

- Heavy Duty High Energy Disc Brakes for Drilling and Service Rigs

- Dual Operation Service and Parking Caliper Disc Brakes Available with self-adjusting option

- Top Drives Caliper Disc Brakes

- Air, Hydraulic, or Electric Actuation Available

- Organic or Sintered Friction Linings

- Ventilated or Water Cooled Discs Available for greater heat dissipation

- Overrunning Clutches

- Pneumatic or Hydraulic Actuated Clutches with torque capacities ranging from 55,000 t0 1,275,000 pound-inches.

- Standard Clutches and Water Cooled Brakes/Clutches

- Power Units and Controls

- Repair and Retrofit

- OEM and Aftermarket for most major brands. Custom brakes available for unique applications

Friction Materials

- Rigid, woven, and sintered friction products available for brake pads, brake bands, clutch facings

- Reline services available

- Can incorporate a variety of AC or DC motor and compressor combinations

- Feature control valves, filters, regulators, lubricators

Bushings

Mud Pumps

Couplings

Bearings

Gears and Gearboxes

Bushings

Mud Pumps

Couplings

Bearings

Gears and Gearboxes Motors

Rope Drums

Variable Frequency Drives

Repair, Retrofit, and Engineering Services

At Your Service

Motors

Rope Drums

Variable Frequency Drives

Repair, Retrofit, and Engineering Services

At Your Service At Kor-Pak, we understand how important efficiency is and the severe costs of downtime. That is why we offer 24 hour customer support and you can submit a Ticket to reach out to a Kor-Pak representative anytime to obtain the information you need. Kor-Pak possesses the expertise, experience, and customer-focused attitude required to help you with your product or application-related question to keep you equipment running at optimal efficiency.

Kor-Pak is your premier source for Oil Rig Equipment Kor-Pak is a manufacturer and distributor for various Oil Rig products, including:

At Kor-Pak, we understand how important efficiency is and the severe costs of downtime. That is why we offer 24 hour customer support and you can submit a Ticket to reach out to a Kor-Pak representative anytime to obtain the information you need. Kor-Pak possesses the expertise, experience, and customer-focused attitude required to help you with your product or application-related question to keep you equipment running at optimal efficiency.

Kor-Pak is your premier source for Oil Rig Equipment Kor-Pak is a manufacturer and distributor for various Oil Rig products, including:Brakes, Clutches, and Accessories

- Heavy Duty High Energy Disc Brakes for Drilling and Service Rigs

- Dual Operation Service and Parking Caliper Disc Brakes Available with self-adjusting option

- Top Drives Caliper Disc Brakes

- Air, Hydraulic, or Electric Actuation Available

- Organic or Sintered Friction Linings

- Ventilated or Water Cooled Discs Available for greater heat dissipation

- Overrunning Clutches

- Pneumatic or Hydraulic Actuated Clutches with torque capacities ranging from 55,000 t0 1,275,000 pound-inches.

- Standard Clutches and Water Cooled Brakes/Clutches

- Power Units and Controls

- Repair and Retrofit

- OEM and Aftermarket for most major brands. Custom brakes available for unique applications

Friction Materials

- Rigid, woven, and sintered friction products available for brake pads, brake bands, clutch facings

- Reline services available

- Can incorporate a variety of AC or DC motor and compressor combinations

- Feature control valves, filters, regulators, lubricators

Paper Mill Friction Materials (3)

Paper Mill Friction Materials (3)

Pintsch Bubenzer Brakes (62)

Pintsch Bubenzer Brakes (62)

Power-Transmission-Spare-Parts (5711)..

Power-Transmission-Spare-Parts-and-Assemblies (5711)

Scan-Pac Distributor (11)

Scan-Pac Distributor (11)

Kor-Pak Corporation has a rich history with Scan-Pac Manufacturing as Kor-Pak founder Jim Koralik helped Scan-Pac founder Skip Scandrett pioneer non-asbestos friction materials into various markets to be used in a plethora of applications. In the early 1980's, Kor-Pak helped iron and steel plants create non-asbestos Overhead Crane (OHC) linings for DC magnetic shoe brakes, creating molds for rigid organic linings using the flagship RF-38 material which is a mainstay for hoist applications.

Subsequently, Kor-Pak began designing and implementing Scan-Pac friction and phenolic materials for other applications: woven brake blocks for oilfield applications, flexible friction materials used for brake bands for agricultural applications, rigid brake pads for off-highway vehicles, and several others.

Today, Scan-Pac manufactures literally dozens of friction materials with varying friction coefficients and other technical properties and there is rarely, if ever, an application that Scan-Pac friction materials cannot successfully accommodate. Kor-Pak possesses the value-added capabilities and engineering services required to help you with your friction materials needs.

Gemini Friction Materials

Scan-Pac Mfg. developed the Gemini Brand of friction materials to provide the most cost effective friction materials for industrial and oilfield applications. In the Gemini line, there are four rigid molded formulations with coefficients of friction ranging from .15 to .59 and a woven material to meet the needs of industrial and oilfield applications. The line consists of GL (Gemini Low), GM (Gemini Mid), GMH (Gemini Mid-High) and GH (Gemini High).

Gatke Phenolics and Laminates

The Gatke Corporation was acquired by Scan-Pac several years ago as a strategic acquisition to complement its preexisting product line. This was a prudent decision as Gatke is a unique and versatile product line that can be used ubiquitously for several industries and applications.

There are several grades of Gatke material available with different material compositions that enable them to be utilized for various applications. Gatke products can be found in applications such as Rail (Equalizer Seats, Center Plates, and Vertical Liners), Iron and Steel (roll stand bearings), Agriculture (phenolic bushings), Screw Conveyors (hanger bearings), and many more. Gatke is often an ideal alternative to metal as it has self-lubricating characteristics which make it forgiving and having a longer wear life than its other more abrasive and less environmentally-friendly competitors. Contact a Kor-Pak representative today to help you find the ideal phenolic/laminate material for your applications.Kor-Pak Corporation has a rich history with Scan-Pac Manufacturing as Kor-Pak founder Jim Koralik helped Scan-Pac founder Skip Scandrett pioneer non-asbestos friction materials into various markets to be used in a plethora of applications. In the early 1980's, Kor-Pak helped iron and steel plants create non-asbestos Overhead Crane (OHC) linings for DC magnetic shoe brakes, creating molds for rigid organic linings using the flagship RF-38 material which is a mainstay for hoist applications. Subsequently, Kor-Pak began designing and implementing Scan-Pac friction and phenolic materials for other applications: woven brake blocks for oilfield applications, flexible friction materials used for brake bands for agricultural applications, rigid brake pads for off-highway vehicles, and several others. Today, Scan-Pac manufactures literally dozens of friction materials with varying friction coefficients and other technical properties and there is rarely, if ever, an application that Scan-Pac friction materials cannot successfully accommodate. Kor-Pak possesses the value-added capabilities and engineering services required to help you with your friction materials needs. Gemini Friction Materials Scan-Pac Mfg. developed the Gemini Brand of friction materials to provide the most cost effective friction materials for industrial and oilfield applications. In the Gemini line, there are four rigid molded formulations with coefficients of friction ranging from .15 to .59 and a woven material to meet the needs of industrial and oilfield applications. The line consists of GL (Gemini Low), GM (Gemini Mid), GMH (Gemini Mid-High) and GH (Gemini High). Gatke Phenolics and Laminates The Gatke Corporation was acquired by Scan-Pac several years ago as a strategic acquisition to complement its preexisting product line. This was a prudent decision as Gatke is a unique and versatile product line that can be used ubiquitously for several industries and applications. There are several grades of Gatke material available with different material compositions that enable them to be utilized for various applications. Gatke products can be found in applications such as Rail (Equalizer Seats, Center Plates, and Vertical Liners), Iron and Steel (roll stand bearings), Agriculture (phenolic bushings), Screw Conveyors (hanger bearings), and many more. Gatke is often an ideal alternative to metal as it has self-lubricating characteristics which make it forgiving and having a longer wear life than its other more abrasive and less environmentally-friendly competitors. Contact a Kor-Pak representative today to help you find the ideal phenolic/laminate material for your applications.

Kor-Pak Corporation has a rich history with Scan-Pac Manufacturing as Kor-Pak founder Jim Koralik helped Scan-Pac founder Skip Scandrett pioneer non-asbestos friction materials into various markets to be used in a plethora of applications. In the early 1980's, Kor-Pak helped iron and steel plants create non-asbestos Overhead Crane (OHC) linings for DC magnetic shoe brakes, creating molds for rigid organic linings using the flagship RF-38 material which is a mainstay for hoist applications.

Subsequently, Kor-Pak began designing and implementing Scan-Pac friction and phenolic materials for other applications: woven brake blocks for oilfield applications, flexible friction materials used for brake bands for agricultural applications, rigid brake pads for off-highway vehicles, and several others.

Today, Scan-Pac manufactures literally dozens of friction materials with varying friction coefficients and other technical properties and there is rarely, if ever, an application that Scan-Pac friction materials cannot successfully accommodate. Kor-Pak possesses the value-added capabilities and engineering services required to help you with your friction materials needs.

Gemini Friction Materials

Scan-Pac Mfg. developed the Gemini Brand of friction materials to provide the most cost effective friction materials for industrial and oilfield applications. In the Gemini line, there are four rigid molded formulations with coefficients of friction ranging from .15 to .59 and a woven material to meet the needs of industrial and oilfield applications. The line consists of GL (Gemini Low), GM (Gemini Mid), GMH (Gemini Mid-High) and GH (Gemini High).

Gatke Phenolics and Laminates

The Gatke Corporation was acquired by Scan-Pac several years ago as a strategic acquisition to complement its preexisting product line. This was a prudent decision as Gatke is a unique and versatile product line that can be used ubiquitously for several industries and applications.

There are several grades of Gatke material available with different material compositions that enable them to be utilized for various applications. Gatke products can be found in applications such as Rail (Equalizer Seats, Center Plates, and Vertical Liners), Iron and Steel (roll stand bearings), Agriculture (phenolic bushings), Screw Conveyors (hanger bearings), and many more. Gatke is often an ideal alternative to metal as it has self-lubricating characteristics which make it forgiving and having a longer wear life than its other more abrasive and less environmentally-friendly competitors. Contact a Kor-Pak representative today to help you find the ideal phenolic/laminate material for your applications.Kor-Pak Corporation has a rich history with Scan-Pac Manufacturing as Kor-Pak founder Jim Koralik helped Scan-Pac founder Skip Scandrett pioneer non-asbestos friction materials into various markets to be used in a plethora of applications. In the early 1980's, Kor-Pak helped iron and steel plants create non-asbestos Overhead Crane (OHC) linings for DC magnetic shoe brakes, creating molds for rigid organic linings using the flagship RF-38 material which is a mainstay for hoist applications. Subsequently, Kor-Pak began designing and implementing Scan-Pac friction and phenolic materials for other applications: woven brake blocks for oilfield applications, flexible friction materials used for brake bands for agricultural applications, rigid brake pads for off-highway vehicles, and several others. Today, Scan-Pac manufactures literally dozens of friction materials with varying friction coefficients and other technical properties and there is rarely, if ever, an application that Scan-Pac friction materials cannot successfully accommodate. Kor-Pak possesses the value-added capabilities and engineering services required to help you with your friction materials needs. Gemini Friction Materials Scan-Pac Mfg. developed the Gemini Brand of friction materials to provide the most cost effective friction materials for industrial and oilfield applications. In the Gemini line, there are four rigid molded formulations with coefficients of friction ranging from .15 to .59 and a woven material to meet the needs of industrial and oilfield applications. The line consists of GL (Gemini Low), GM (Gemini Mid), GMH (Gemini Mid-High) and GH (Gemini High). Gatke Phenolics and Laminates The Gatke Corporation was acquired by Scan-Pac several years ago as a strategic acquisition to complement its preexisting product line. This was a prudent decision as Gatke is a unique and versatile product line that can be used ubiquitously for several industries and applications. There are several grades of Gatke material available with different material compositions that enable them to be utilized for various applications. Gatke products can be found in applications such as Rail (Equalizer Seats, Center Plates, and Vertical Liners), Iron and Steel (roll stand bearings), Agriculture (phenolic bushings), Screw Conveyors (hanger bearings), and many more. Gatke is often an ideal alternative to metal as it has self-lubricating characteristics which make it forgiving and having a longer wear life than its other more abrasive and less environmentally-friendly competitors. Contact a Kor-Pak representative today to help you find the ideal phenolic/laminate material for your applications.

Sibre Brakes (90)

Sibre Brakes (90)

Stearns Parts (5980)

Stearns Parts (5980)

Svendborg Brakes (57)

Svendborg Brakes (57)

Torque Limiters (3)

Torque Limiters (3)

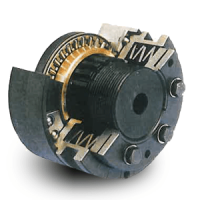

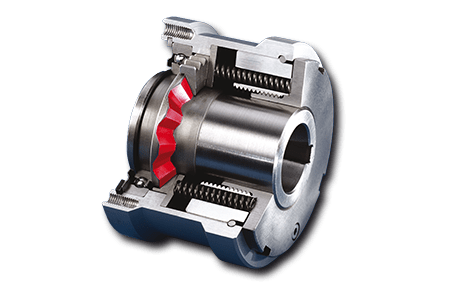

TORQUE OVERLOAD PROTECTION DEVICES

Kor-Pak offers several lines and version of Torque Limiters, representing a number of brand-names that serve customers and industries around the globe.

WHY A TORQUE LIMITER?

The objective of torque overload devices is to assure efficient protection of man and machine against momentary overload conditions. A Torque limiter is a mechanical protection device which, when an overload happens, the load separates from the drive. The limiters with rotating elements (balls or rollers) can be provided with a limit switch. This permits control of the motor drive system and to stop the machine e.g. Emergency Stop. Friction (single or multi discs) Wet or dry use Balls-Races or Rollers Synchronised Torque adjustment For Lifting Devices With/Without Coupling Torque range: 5 to 25 600 NmTORQUE OVERLOAD PROTECTION DEVICES

Kor-Pak offers several lines and version of Torque Limiters, representing a number of brand-names that serve customers and industries around the globe.WHY A TORQUE LIMITER?

The objective of torque overload devices is to assure efficient protection of man and machine against momentary overload conditions. A Torque limiter is a mechanical protection device which, when an overload happens, the load separates from the drive. The limiters with rotating elements (balls or rollers) can be provided with a limit switch. This permits control of the motor drive system and to stop the machine e.g. Emergency Stop. Friction (single or multi discs) Wet or dry use Balls-Races or Rollers Synchronised Torque adjustment For Lifting Devices With/Without Coupling Torque range: 5 to 25 600 Nm

Twiflex Brakes (35)

Twiflex Brakes (35)

WPT Power Brakes (2)

WPT Power Brakes (2)

YAW Brakes (7)

YAW Brakes (7)

A full array of caliper solutions is available from Kor-Pak to meet the yaw braking force requirements of any size wind turbine / wind energy brakes needs. All brake models are robust, hydraulically activated, and direct applied. Models with up to 40kN braking force, featuring two-bolt side mounting, are designed for light to medium-duty applications. We also have brake models featuring four-bolt center mounting, is ideal for use in medium sized turbines. Our base mounted caliper is designed for larger, heavy-duty turbine applications.

All models of yaw brakes function as static holding brakes when the nacelle is positioned into the wind. Typically, Kor-Pak caliper brakes may act directly on the yaw ring or Matrix plate-type brakes are mounted on the non-driving end of the yaw motors.A full array of caliper solutions is available from Kor-Pak to meet the yaw braking force requirements of any size wind turbine / wind energy brakes needs. All brake models are robust, hydraulically activated, and direct applied. Models with up to 40kN braking force, featuring two-bolt side mounting, are designed for light to medium-duty applications. We also have brake models featuring four-bolt center mounting, is ideal for use in medium sized turbines. Our base mounted caliper is designed for larger, heavy-duty turbine applications. All models of yaw brakes function as static holding brakes when the nacelle is positioned into the wind. Typically, Kor-Pak caliper brakes may act directly on the yaw ring or Matrix plate-type brakes are mounted on the non-driving end of the yaw motors.

applied. Models with up to 40kN braking force, featuring two-bolt side mounting, are designed for light to medium-duty applications. We also have brake models featuring four-bolt center mounting, is ideal for use in medium sized turbines. Our base mounted caliper is designed for larger, heavy-duty turbine applications.

All models of yaw brakes function as static holding brakes when the nacelle is positioned into the wind. Typically, Kor-Pak caliper brakes may act directly on the yaw ring or Matrix plate-type brakes are mounted on the non-driving end of the yaw motors.A full array of caliper solutions is available from Kor-Pak to meet the yaw braking force requirements of any size wind turbine / wind energy brakes needs. All brake models are robust, hydraulically activated, and direct applied. Models with up to 40kN braking force, featuring two-bolt side mounting, are designed for light to medium-duty applications. We also have brake models featuring four-bolt center mounting, is ideal for use in medium sized turbines. Our base mounted caliper is designed for larger, heavy-duty turbine applications. All models of yaw brakes function as static holding brakes when the nacelle is positioned into the wind. Typically, Kor-Pak caliper brakes may act directly on the yaw ring or Matrix plate-type brakes are mounted on the non-driving end of the yaw motors.

Industrial Brakes & Clutch (120)..

Industrial Brakes & Clutches (120)

Kor-Pak Corporation is an industrial brake and clutch specialist. Not only do we offer a plethora of brakes and clutches in terms of size, torque, styles, and applications, but we also design custom brakes and clutches, offer design and application engineering, and have a robust service and aftermarket segment that will enable you to recondition your existing equipment and source OEM and aftermarket parts at competitive prices. No matter what the application, Kor-Pak can help you find what you need and our customer-focused and hands-on approach will ensure that you are always receiving the support and attention you need to keep your equipment running at optimal efficiency.

As you navigate the website you will find many different brakes and clutches offered by Kor-Pak, and if you cannot find what you're looking for please contact a Kor-Pak representative today to help you.

For more information on industrial brake wheels, click here Related Literature: Kor-Pak Brochure Kor-Pak Brochure- Oil and Gas 2014 Crane Symposium PowerPoint

Kor-Pak Corporation is an industrial brake and clutch specialist. Not only do we offer a plethora of brakes and clutches in terms of size, torque, styles, and applications, but we also design custom brakes and clutches, offer design and application engineering, and have a robust service and aftermarket segment that will enable you to recondition your existing equipment and source OEM and aftermarket parts at competitive prices. No matter what the application, Kor-Pak can help you find what you need and our customer-focused and hands-on approach will ensure that you are always receiving the support and attention you need to keep your equipment running at optimal efficiency.

As you navigate the website you will find many different brakes and clutches offered by Kor-Pak, and if you cannot find what you're looking for please contact a Kor-Pak representative today to help you.

For more information on industrial brake wheels, click here Related Literature: Kor-Pak Brochure Kor-Pak Brochure- Oil and Gas 2014 Crane Symposium PowerPointIndustrial DRUM Brakes

Kor-Pak can supply various styles of drum/shoe brakes that conform either AISE or DIN standards. Our drum brakes are fail-safe, spring-set and electro-hydraulic thruster or magnetically released. We can also provide all spare products and accompanying items such as brake drums, shoes, thrusters, coils (both shunt and series wound), controllers, and spare parts.DISC Brakes

offers a diverse portfolio of industrial disc brakes that cater to a wide variety of applications. Our wide range of caliper disc brakes are offered as either hydraulic or air applied/spring released, or spring applied and hydraulic, air, or magnetically released. Our robust caliper disc brakes are used ubiquitously and can be found in numerous unique applications and they can furnish extremely high torque requirements and concurrently withstand the harshest of environmental conditions.STORM / PARKING BRAKES

Our innovative and diverse selection of storm and rail brakes have helped industries persevere throughout harsh and demanding environments. Whether it be intense winds, seismic activity, or bracing your container when incurring heavy loads, Kor-Pak’s Storm Brakes will enable you to overcome these obstacles and achieve your industry-specific goals. Kor-Pak offers several options of Storm Brakes including: rail clamps, wheel grippers, rail grippers, and corresponding accessories. These are offered with various mounting options such as sill-beam, flange, or truck mounted and our rail clamps can be furnished with integral power units.Kor-Pak Corporation is an industrial brake and clutch specialist. Not only do we offer a plethora of brakes and clutches in terms of size, torque, styles, and applications, but we also design custom brakes and clutches, offer design and application engineering, and have a robust service and aftermarket segment that will enable you to recondition your existing equipment and source OEM and aftermarket parts at competitive prices. No matter what the application, Kor-Pak can help you find what you need and our customer-focused and hands-on approach will ensure that you are always receiving the support and attention you need to keep your equipment running at optimal efficiency. As you navigate the website you will find many different brakes and clutches offered by Kor-Pak, and if you cannot find what you're looking for please contact a Kor-Pak representative today to help you.For more information on industrial brake wheels, click here Related Literature: Kor-Pak Brochure Kor-Pak Brochure- Oil and Gas 2014 Crane Symposium PowerPointIndustrial DRUM Brakes

Kor-Pak can supply various styles of drum/shoe brakes that conform either AISE or DIN standards. Our drum brakes are fail-safe, spring-set and electro-hydraulic thruster or magnetically released. We can also provide all spare products and accompanying items such as brake drums, shoes, thrusters, coils (both shunt and series wound), controllers, and spare parts.DISC Brakes

offers a diverse portfolio of industrial disc brakes that cater to a wide variety of applications. Our wide range of caliper disc brakes are offered as either hydraulic or air applied/spring released, or spring applied and hydraulic, air, or magnetically released. Our robust caliper disc brakes are used ubiquitously and can be found in numerous unique applications and they can furnish extremely high torque requirements and concurrently withstand the harshest of environmental conditions.STORM / PARKING BRAKES

Our innovative and diverse selection of storm and rail brakes have helped industries persevere throughout harsh and demanding environments. Whether it be intense winds, seismic activity, or bracing your container when incurring heavy loads, Kor-Pak’s Storm Brakes will enable you to overcome these obstacles and achieve your industry-specific goals. Kor-Pak offers several options of Storm Brakes including: rail clamps, wheel grippers, rail grippers, and corresponding accessories. These are offered with various mounting options such as sill-beam, flange, or truck mounted and our rail clamps can be furnished with integral power units.

Brake and Clutch Accessories (107)

Brake and Clutch Accessories (107)

Kor-Pak is a One-Stop Source for Industrial Brake and Clutch Accessories and Spare Parts

Preventive maintenance and inventory management are crucial to the consistency and reliability of your equipment. Kor-Pak can equip you with the accessories and spare parts you need to help you maintain operational efficiency. [caption id="attachment_4273" align="alignright" width="363"] DC Coils for Magnetic Drum Brakes and DC Control Panels[/caption]

DC Coils for Magnetic Drum Brakes and DC Control Panels[/caption]

DC Magnetic Coils

Shunt & series wound, OEM and aftermarket, also able to supply obsolete coils for major product lines.Electro-Hydraulic Thrusters

- Both Wet and Dry Available (EB and ED), ELDRO and ELHY available to accommodate desired torque range

[caption id="attachment_4271" align="alignright" width="163"]

Electro-hydraulic thrusters[/caption]

Electro-hydraulic thrusters[/caption] - AC or DC

- Special Options available (i.e. Kevlar Dust Boot, explosion proof, lowering valve, high-temp silicone fluid)

Brake Wheels

[caption id="attachment_4269" align="alignright" width="224"] Centered and Offset Brake Wheels, Bored & Keyed to Various Sizes[/caption]

Kor-Pak offers a comprehensive range of brake drums. Standard drum / gear coupling arrangements or custom units

completed to individual specifications. Our drums are made from high quality steel. Our drum designs include:

Centered and Offset Brake Wheels, Bored & Keyed to Various Sizes[/caption]

Kor-Pak offers a comprehensive range of brake drums. Standard drum / gear coupling arrangements or custom units

completed to individual specifications. Our drums are made from high quality steel. Our drum designs include:

Standard & Offset Brake Drums

- with mounting holes, rough stock bore, or bored and keyed as per customer specifications.'Sella' Brake Drums

- completed to DIN 15431 and AISE Standards.'Sella' Flexible Couplings

- multiple arrangements availableFriction Discs

Kor-Pak offers a comprehensive range of brake discs. Standard disc/hub arrangements or custom units. All discs can be completed with tapered bore, dynamic balancing, or any other custom features required. Spare Brake Shoes, Disc Pads, and Relining: Kor-Pak can furnish both OEM and Aftermarket for virtually any brake shoe/disc pad using various types of friction linings for specific applications. Our rigid friction (RF) non-asbestos linings have become the industry standard, and our sintered and semi-metallic linings are ideal for high temperature applications and also reduce braking noise. Kor-Pak also designs/manufactures/reverse engineers custom brake pads to suit your needs. We carry several models and sizes, including: Cutler-Hammer (503 and 505), Square D (Type T and F), Wagner, Johnson/Elevanja, Mondel/P&H, Bubenzer, Whiting, GE, Clark, Zenar, and many more.Friction Discs for Clutches and PTOs

Kor-Pak provides a wide range of Friction Discs for PTO's and Clutches including Twin Disc, WPT, Wichita, Reuland, and Eaton-Airflex. Kor-Pak brand aluminum brake shoes are widely used and successfully implemented on shoe brakes across the United States. Aluminum brake shoes are proven to effectively dissipate heat, and also weigh substantially less than their cast iron counterparts. [highlight]Ask About our exclusive Aluminum Shoes. 50% Lighter, Less Down Time, Added Safety During Changeouts Spare Brake Components: whether it be a spare pin, bushing, spring, lever, high-temperature silicone fluid, friction linings, relief valve, or viton seal, Kor-Pak will provide you with high-quality spare parts to keep your outfit in service. Many Value-Added services are available: We not only manufacture the brake shoe, but also offer bonding of high-quality non-asbestos linings to the brake shoe to create a finished assembly. Related Information: Thruster Selection Sheet Thruster Brochure Discs Brake Drums Couplings

Kor-Pak is a One-Stop Source for Industrial Brake and Clutch Accessories and Spare Parts

Preventive maintenance and inventory management are crucial to the consistency and reliability of your equipment. Kor-Pak can equip you with the accessories and spare parts you need to help you maintain operational efficiency. [caption id="attachment_4273" align="alignright" width="363"] DC Coils for Magnetic Drum Brakes and DC Control Panels[/caption]DC Magnetic Coils

Shunt & series wound, OEM and aftermarket, also able to supply obsolete coils for major product lines.Electro-Hydraulic Thrusters

- Both Wet and Dry Available (EB and ED), ELDRO and ELHY available to accommodate desired torque range [caption id="attachment_4271" align="alignright" width="163"] Electro-hydraulic thrusters[/caption]

- AC or DC

- Special Options available (i.e. Kevlar Dust Boot, explosion proof, lowering valve, high-temp silicone fluid)

Brake Wheels

[caption id="attachment_4269" align="alignright" width="224"] Centered and Offset Brake Wheels, Bored & Keyed to Various Sizes[/caption] Kor-Pak offers a comprehensive range of brake drums. Standard drum / gear coupling arrangements or custom units completed to individual specifications. Our drums are made from high quality steel. Our drum designs include:Standard & Offset Brake Drums

- with mounting holes, rough stock bore, or bored and keyed as per customer specifications.'Sella' Brake Drums

- completed to DIN 15431 and AISE Standards.'Sella' Flexible Couplings

- multiple arrangements availableFriction Discs

Kor-Pak offers a comprehensive range of brake discs. Standard disc/hub arrangements or custom units. All discs can be completed with tapered bore, dynamic balancing, or any other custom features required. Spare Brake Shoes, Disc Pads, and Relining: Kor-Pak can furnish both OEM and Aftermarket for virtually any brake shoe/disc pad using various types of friction linings for specific applications. Our rigid friction (RF) non-asbestos linings have become the industry standard, and our sintered and semi-metallic linings are ideal for high temperature applications and also reduce braking noise. Kor-Pak also designs/manufactures/reverse engineers custom brake pads to suit your needs. We carry several models and sizes, including: Cutler-Hammer (503 and 505), Square D (Type T and F), Wagner, Johnson/Elevanja, Mondel/P&H, Bubenzer, Whiting, GE, Clark, Zenar, and many more.Friction Discs for Clutches and PTOs

Kor-Pak provides a wide range of Friction Discs for PTO's and Clutches including Twin Disc, WPT, Wichita, Reuland, and Eaton-Airflex. Kor-Pak brand aluminum brake shoes are widely used and successfully implemented on shoe brakes across the United States. Aluminum brake shoes are proven to effectively dissipate heat, and also weigh substantially less than their cast iron counterparts. [highlight]Ask About our exclusive Aluminum Shoes. 50% Lighter, Less Down Time, Added Safety During Changeouts Spare Brake Components: whether it be a spare pin, bushing, spring, lever, high-temperature silicone fluid, friction linings, relief valve, or viton seal, Kor-Pak will provide you with high-quality spare parts to keep your outfit in service. Many Value-Added services are available: We not only manufacture the brake shoe, but also offer bonding of high-quality non-asbestos linings to the brake shoe to create a finished assembly. Related Information: Thruster Selection Sheet Thruster Brochure Discs Brake Drums Couplings

Molded & Rigid Friction Pr (2)..

Molded & Rigid Friction Products (2)

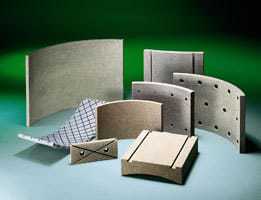

Molded & Rigid Friction Products

Kor-Pak offers a diverse array of molded and rigid friction products which are successfully used in numerous applications. We offer custom fabricated parts as well as molding high volume products to achieve economies of scale. Kor-Pak offers Molded Flat Sheet Products available in sizes and thickness for user fabrication into any desired shape. Quick turnaround of production assures availability in either 20"x 20" or 30"x 30" flat sheets in wide range of available friction levels. Material can either be machined or fabricated by water-jet cutting to desired shape.Rigid Molded Blocks (RF Material)

Non-asbestos rigid molded blocks are the premium product line for use on heavy duty industrial brakes and shoe type clutches. RF materials exhibit smooth consistent friction with excellent properties.

- Wide range of friction levels

- Low wear and abrasion

- Excellent fade resistance

- Smooth, consistent friction

- Heavy duty industrial brakes & shoe clutch applications

- Drilled or undrilled

- Available for most industrial applications

- Both ID and OD geartooth facings available in most sizes and thicknesses

- Most formulations can be molded to special internal or external configurations

- Examples of use: construction or mining machinery clutches, pumping & irrigation drives, punch press brakes & clutches, overload and tensioning devices, winches & hoists, other industrial clutch & brake applications

Molded & Rigid Friction Products

Kor-Pak offers a diverse array of molded and rigid friction products which are successfully used in numerous applications. We offer custom fabricated parts as well as molding high volume products to achieve economies of scale. Kor-Pak offers Molded Flat Sheet Products available in sizes and thickness for user fabrication into any desired shape. Quick turnaround of production assures availability in either 20"x 20" or 30"x 30" flat sheets in wide range of available friction levels. Material can either be machined or fabricated by water-jet cutting to desired shape.Rigid Molded Blocks (RF Material)

Non-asbestos rigid molded blocks are the premium product line for use on heavy duty industrial brakes and shoe type clutches. RF materials exhibit smooth consistent friction with excellent properties.- Wide range of friction levels

- Low wear and abrasion

- Excellent fade resistance

- Smooth, consistent friction

- Heavy duty industrial brakes & shoe clutch applications

- Drilled or undrilled

- Available for most industrial applications

- Both ID and OD geartooth facings available in most sizes and thicknesses

- Most formulations can be molded to special internal or external configurations

- Examples of use: construction or mining machinery clutches, pumping & irrigation drives, punch press brakes & clutches, overload and tensioning devices, winches & hoists, other industrial clutch & brake applications

Geartooth Facings, Insulator P (5)..

Geartooth Facings, Insulator Plates & Molded Cathead Facings (5)

Gatke Phenolic Bearings and La (3)..

Gatke Phenolic Bearings and Laminates (3)

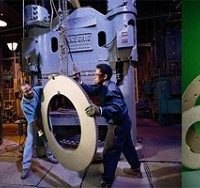

Gatke-Phenolic-Impregnated-Bearings-and-Laminates Kor-Pak is a successful supplier of high-quality Phenolic Impregnated Bearings Laminates that are used in several industries.

[caption id="attachment_522" align="alignright" width="300"]

Kor-Pak is a successful supplier of high-quality Phenolic Impregnated Bearings Laminates that are used in several industries.

[caption id="attachment_522" align="alignright" width="300"] Flat molded plates are used in numerous wear, impact and pressure applications. The unique properties of Gatke materials along with the ease of fabricating parts into numerous configurations, makes Gatke an excellent choice for your critical wear applications.[/caption]