Industrial Brakes & Clutches

Kor-Pak Corporation is an industrial brake and clutch specialist. Not only do we offer a plethora of brakes and clutches in terms of size, torque, styles, and applications, but we also design custom brakes and clutches, offer design and application engineering, and have a robust service and aftermarket segment that will enable you to recondition your existing equipment and source OEM and aftermarket parts at competitive prices. No matter what the application, Kor-Pak can help you find what you need and our customer-focused and hands-on approach will ensure that you are always receiving the support and attention you need to keep your equipment running at optimal efficiency.

Kor-Pak Corporation is an industrial brake and clutch specialist. Not only do we offer a plethora of brakes and clutches in terms of size, torque, styles, and applications, but we also design custom brakes and clutches, offer design and application engineering, and have a robust service and aftermarket segment that will enable you to recondition your existing equipment and source OEM and aftermarket parts at competitive prices. No matter what the application, Kor-Pak can help you find what you need and our customer-focused and hands-on approach will ensure that you are always receiving the support and attention you need to keep your equipment running at optimal efficiency.

As you navigate the website you will find many different brakes and clutches offered by Kor-Pak, and if you cannot find what you’re looking for please contact a Kor-Pak representative today to help you.

Industrial DRUM Brakes

Kor-Pak can supply various styles of drum/shoe brakes that conform either AISE or DIN standards. Our drum brakes are fail-safe, spring-set and electro-hydraulic thruster or magnetically released. We can also provide all spare products and accompanying items such as brake drums, shoes, thrusters, coils (both shunt and series wound), controllers, and spare parts.

DISC Brakes

offers a diverse portfolio of industrial disc brakes that cater to a wide variety of applications. Our wide range of caliper disc brakes are offered as either hydraulic or air applied/spring released, or spring applied and hydraulic, air, or magnetically released. Our robust caliper disc brakes are used ubiquitously and can be found in numerous unique applications and they can furnish extremely high torque requirements and concurrently withstand the harshest of environmental conditions.

STORM / PARKING BRAKES

Our innovative and diverse selection of storm and rail brakes have helped industries persevere throughout harsh and demanding environments. Whether it be intense winds, seismic activity, or bracing your container when incurring heavy loads, Kor-Pak’s Storm Brakes will enable you to overcome these obstacles and achieve your industry-specific goals. Kor-Pak offers several options of Storm Brakes including: rail clamps, wheel grippers, rail grippers, and corresponding accessories. These are offered with various mounting options such as sill-beam, flange, or truck mounted and our rail clamps can be furnished with integral power units.

For more information on industrial brake wheels, click here

Related Literature:

Showing 1–16 of 120 results

-

Eaton Airflex Clutches and Bra (4)..

Eaton Airflex Clutches and Brakes (4)

Kor-Pak offers Eaton Airflex Clutches and Brakes

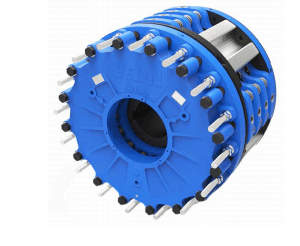

The signature Airflex air-cooled disc clutches and brakes are which are custom designed to provide optimal braking solutions in various application. Eaton Airflex Brakes and Clutches feature a favorable torque-to-size ratios and low-inertia friction disc assemblies, they provide maximum braking performance in limited spaces.Take a Look Inside the Airflex Product Offerings:

[caption id="attachment_2160" align="alignright" width="300"] Eaton Airflex Water Cooled Brake[/caption]

Airflex Water Cooled Third Generation Brake Airflex Third Generation Water Cooled Brake

Eaton Airflex Water Cooled Brake[/caption]

Airflex Water Cooled Third Generation Brake Airflex Third Generation Water Cooled Brake

Air Cooled Disc Clutches & Brakes

Featuring favorable torque-to-size ratios and low-inertia friction disc assemblies, Eaton's Airflex air-cooled disc clutches and brakes are designed to excel in a wide range of applications.Combination Clutch/Brake Packages

Featuring a range of speeds, engagements and cycle types, Eaton Airflex AMCB, CBC, FSPA and DCB clutch and brake packages excel in a variety of specific applications.Expanding Clutches and Brakes

Eaton Airflex Expanding Clutches and Brakes are go-to solutions for braking and tensioning applications, and come in four different series spanning a range of sizes and features.Quick Release Valves

Eaton Airflex Quick Release Valves (QRVs) are engineered to automatically close upon pressurization and open when a pressure drop occurs—reducing lag time to exhaust the system.Spring Applied Drum Brakes

Automatically engaging in the event of air pressure or power loss, Eaton Airflex Spring-Applied Drum Brakes are perfect matches for many moderate-speed, high-torque cyclic applications.Caliper Disc Brakes

Engineered with opposed piston designs and symmetrical split construction, Eaton Airflex DP and DPA caliper disc brakes maximize flexibility and help balance braking performance.Constricting Clutches and Brakes

Drum-style Eaton Airflex constricting clutches and brakes are available with a variety of torque capacities and other features to meet the requirements of the most demanding jobs.Oil and Oil/Air Cooled Multiple Disc Clutches & Brakes

When paired with a spray, splash or through-the-shaft lubricating system, Eaton Airflex Oil- or Oil/Air-Cooled Multiple-Disc Hydraulic Clutches easily manage high-torque applications with small envelope ratios.Rotorseals

Eaton Airflex Rotorseals transfer pressurized fluids from a stationary inlet to a rotating shaft end, providing individual control of components mounted on the same shaft, component lubrication and circulation of fluid systems.Water-Cooled Brakes

Eaton Airflex has developed four models of Water-Cooled Brakes with different advanced features and characteristics to meet the requirements of even the most severe applications. Take a look at the Eaton Airflex Water Cooled Brakes Brochure.Eaton Airflex Literature:

Air Cooled Disc Clutches and Brakes Airflex Third Generation Water Cooled Brake DBA and DBB Brochure DBA Tech Specs DBA Brochure Eaton Airflex Website Eaton Airflex Air Cooled Clutches and Brakes Eaton Airflex Application ProceduresKor-Pak offers Eaton Airflex Clutches and Brakes

The signature Airflex air-cooled disc clutches and brakes are which are custom designed to provide optimal braking solutions in various application. Eaton Airflex Brakes and Clutches feature a favorable torque-to-size ratios and low-inertia friction disc assemblies, they provide maximum braking performance in limited spaces.Take a Look Inside the Airflex Product Offerings:

[caption id="attachment_2160" align="alignright" width="300"] Eaton Airflex Water Cooled Brake[/caption] Airflex Water Cooled Third Generation Brake Airflex Third Generation Water Cooled BrakeAir Cooled Disc Clutches & Brakes

Featuring favorable torque-to-size ratios and low-inertia friction disc assemblies, Eaton's Airflex air-cooled disc clutches and brakes are designed to excel in a wide range of applications.Combination Clutch/Brake Packages

Featuring a range of speeds, engagements and cycle types, Eaton Airflex AMCB, CBC, FSPA and DCB clutch and brake packages excel in a variety of specific applications.Expanding Clutches and Brakes

Eaton Airflex Expanding Clutches and Brakes are go-to solutions for braking and tensioning applications, and come in four different series spanning a range of sizes and features.Quick Release Valves

Eaton Airflex Quick Release Valves (QRVs) are engineered to automatically close upon pressurization and open when a pressure drop occurs—reducing lag time to exhaust the system.Spring Applied Drum Brakes

Automatically engaging in the event of air pressure or power loss, Eaton Airflex Spring-Applied Drum Brakes are perfect matches for many moderate-speed, high-torque cyclic applications.Caliper Disc Brakes

Engineered with opposed piston designs and symmetrical split construction, Eaton Airflex DP and DPA caliper disc brakes maximize flexibility and help balance braking performance.Constricting Clutches and Brakes

Drum-style Eaton Airflex constricting clutches and brakes are available with a variety of torque capacities and other features to meet the requirements of the most demanding jobs.Oil and Oil/Air Cooled Multiple Disc Clutches & Brakes

When paired with a spray, splash or through-the-shaft lubricating system, Eaton Airflex Oil- or Oil/Air-Cooled Multiple-Disc Hydraulic Clutches easily manage high-torque applications with small envelope ratios.Rotorseals

Eaton Airflex Rotorseals transfer pressurized fluids from a stationary inlet to a rotating shaft end, providing individual control of components mounted on the same shaft, component lubrication and circulation of fluid systems.Water-Cooled Brakes

Eaton Airflex has developed four models of Water-Cooled Brakes with different advanced features and characteristics to meet the requirements of even the most severe applications. Take a look at the Eaton Airflex Water Cooled Brakes Brochure.Eaton Airflex Literature:

Air Cooled Disc Clutches and Brakes Airflex Third Generation Water Cooled Brake DBA and DBB Brochure DBA Tech Specs DBA Brochure Eaton Airflex Website Eaton Airflex Air Cooled Clutches and Brakes Eaton Airflex Application Procedures -

Hydraulic Caliper Disc Brakes (17)

Hydraulic Caliper Disc Brakes (17)

KOR-PAK HYDRAULIC CALIPER DISC BRAKES

Kor-Pak provides an extensive portfolio of spring-set, hydraulic released caliper disc brakes that can accommodate extremely high torque requirements.

Our brakes are used in applications around the world including: drawworks, grinding mills, conveyors, crane/hoist, winches, ship loaders/unloaders, and many others. Our lever and direct-acting caliper disc brakes contain features that create long life and the capability of withstanding harsh environmental conditions. Whether it be designing brakes for a new application or retrofitting an existing one, Kor-Pak will meet your needs and provide you with hydraulic disc brakes that offer safe and reliable braking.

Lever Actuated Hydraulic Caliper Disc Brakes:

- Spring Set / Hydraulic Released Disc Brakes

- Hydraulic set / Spring Released Disc Brakes

[caption id="attachment_1904" align="alignright" width="300"]

KOR-PAK HYDRAULIC CALIPER DISC BRAKES

Kor-Pak provides an extensive portfolio of spring-set, hydraulic released caliper disc brakes that can accommodate extremely high torque requirements.

Our brakes are used in applications around the world including: drawworks, grinding mills, conveyors, crane/hoist, winches, ship loaders/unloaders, and many others. Our lever and direct-acting caliper disc brakes contain features that create long life and the capability of withstanding harsh environmental conditions. Whether it be designing brakes for a new application or retrofitting an existing one, Kor-Pak will meet your needs and provide you with hydraulic disc brakes that offer safe and reliable braking.

Lever Actuated Hydraulic Caliper Disc Brakes:

- Spring Set / Hydraulic Released Disc Brakes

- Hydraulic set / Spring Released Disc Brakes

[caption id="attachment_1904" align="alignright" width="300"] Hydraulic Caliper Lever Brake used on log handling crane[/caption]

Hydraulic Caliper Lever Brake used on log handling crane[/caption]

- MECHANISM - free-floating when set and self-centering when released

- ACTUATION - spring set / hydraulic released, hydraulic set / spring released - spring compensated

- MOUNTING - foot-mount or side-mount, actuators either handing

- CONSTRUCTION - steel and ductile iron, or aluminum shoes, stainless steel pins standard

- CONFIGURATION - single or double actuator, offset to either side of brake disc

- LININGS - non-asbestos compositions to suit application requirements

- DISCS - solid or ventilated, carbon or stainless steel, cast iron or non-ferrous

- OPTIONS - special alloys, coatings, controls and custom mountings

- APPLICATIONS -hoists / winches, conveyers, drives, processing machines

- ENGINEERING -application and selection assistance available

Direct Acting Caliper Brake Used for Drawworks[/caption]

Fast acting, requiring little maintenance and almost no lubrication, accommodating several applications and can endure harsh operating environments. Used successfully for many applications such as emergency braking systems for Container Cranes and Ladle Cranes, Drawworks, Conveyors, and Logging Mills.

Direct Spring Brake Features:

Direct Acting Caliper Brake Used for Drawworks[/caption]

Fast acting, requiring little maintenance and almost no lubrication, accommodating several applications and can endure harsh operating environments. Used successfully for many applications such as emergency braking systems for Container Cranes and Ladle Cranes, Drawworks, Conveyors, and Logging Mills.

Direct Spring Brake Features:

- Spring set, hydraulic pressure release

- Self-contained removable actuators

- Many spring stack options

- Stroke / wear adjustment

- Spring caging feature

- Hydraulic pressure isolated from disc

- Actuator manual release / retraction

- Fixed assemblies with opposing actuators

- Floating assemblies with low friction float bearings

- Floating assemblies with single or opposing actuators

- Narrow profile with actuators on one side

- Single and multiple actuator assemblies

- Optional bases for fixed and floating assemblies

- Optional release and wear proximity - switches

- Flow through actuators - better oil filtering

KOR-PAK HYDRAULIC CALIPER DISC BRAKES Kor-Pak provides an extensive portfolio of spring-set, hydraulic released caliper disc brakes that can accommodate extremely high torque requirements. Our brakes are used in applications around the world including: drawworks, grinding mills, conveyors, crane/hoist, winches, ship loaders/unloaders, and many others. Our lever and direct-acting caliper disc brakes contain features that create long life and the capability of withstanding harsh environmental conditions. Whether it be designing brakes for a new application or retrofitting an existing one, Kor-Pak will meet your needs and provide you with hydraulic disc brakes that offer safe and reliable braking. Lever Actuated Hydraulic Caliper Disc Brakes: - Spring Set / Hydraulic Released Disc Brakes - Hydraulic set / Spring Released Disc Brakes [caption id="attachment_1904" align="alignright" width="300"] Hydraulic Caliper Lever Brake used on log handling crane[/caption]- MECHANISM - free-floating when set and self-centering when released

- ACTUATION - spring set / hydraulic released, hydraulic set / spring released - spring compensated

- MOUNTING - foot-mount or side-mount, actuators either handing

- CONSTRUCTION - steel and ductile iron, or aluminum shoes, stainless steel pins standard

- CONFIGURATION - single or double actuator, offset to either side of brake disc

- LININGS - non-asbestos compositions to suit application requirements

- DISCS - solid or ventilated, carbon or stainless steel, cast iron or non-ferrous

- OPTIONS - special alloys, coatings, controls and custom mountings

- APPLICATIONS -hoists / winches, conveyers, drives, processing machines

- ENGINEERING -application and selection assistance available

- Spring set, hydraulic pressure release

- Self-contained removable actuators

- Many spring stack options

- Stroke / wear adjustment

- Spring caging feature

- Hydraulic pressure isolated from disc

- Actuator manual release / retraction

- Fixed assemblies with opposing actuators

- Floating assemblies with low friction float bearings

- Floating assemblies with single or opposing actuators

- Narrow profile with actuators on one side

- Single and multiple actuator assemblies

- Optional bases for fixed and floating assemblies

- Optional release and wear proximity - switches

- Flow through actuators - better oil filtering

-

Johnson Brakes (19)

Johnson Brakes (19)

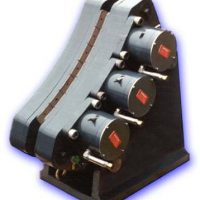

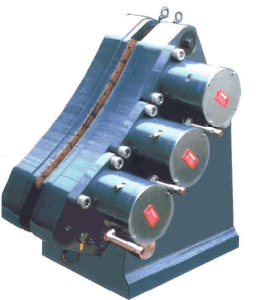

About KJohnson/Elevanja

For over two decades, Kor-Pak Corporation has been a dealer/distributor for ohnson/Elevanja Industrial Braking Systems. Johnson Industries Ltd. was founded in 1966 in Richmond, B.C., and in 1993 acquired the British brake manufacturer Elevanja. Johnson Industries' strategic acquisitions, ingenuity, superior engineering, and entrepreneurial spirit has enabled it to become a premier brake manufacturer with a dominant global presence. In 2015, Elevanja will be celebrating it's 100th anniversary and Johnson Industries offers by far the most diversified and innovative brake portfolio in the marketplace. In the early 1990's, Kor-Pak founder Jim Koralik introduced Johnson electric brakes to the United States Steel Industry as the Johnson Thruster Style brakes, magnetic disc brakes, and emergency caliper brakes have become popular in EOT crane applications. Today, Kor-Pak possesses the knowledge assets and product knowledge to represent Johnson Industries Brakes in a variety of markets such as steel, mining, oil/petroleum, logging, and marine. We service clients around the world and offer 24/7 support to help our clients keep their equipment running at optimal efficiency. Contact a Kor-Pak representative to learn more about Johnson Industries brakes and allow us to serve your industrial braking system needs.

[caption id="attachment_1438" align="alignright" width="231"]

manufacturer Elevanja. Johnson Industries' strategic acquisitions, ingenuity, superior engineering, and entrepreneurial spirit has enabled it to become a premier brake manufacturer with a dominant global presence. In 2015, Elevanja will be celebrating it's 100th anniversary and Johnson Industries offers by far the most diversified and innovative brake portfolio in the marketplace. In the early 1990's, Kor-Pak founder Jim Koralik introduced Johnson electric brakes to the United States Steel Industry as the Johnson Thruster Style brakes, magnetic disc brakes, and emergency caliper brakes have become popular in EOT crane applications. Today, Kor-Pak possesses the knowledge assets and product knowledge to represent Johnson Industries Brakes in a variety of markets such as steel, mining, oil/petroleum, logging, and marine. We service clients around the world and offer 24/7 support to help our clients keep their equipment running at optimal efficiency. Contact a Kor-Pak representative to learn more about Johnson Industries brakes and allow us to serve your industrial braking system needs.

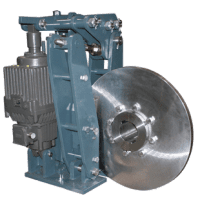

[caption id="attachment_1438" align="alignright" width="231"] Johnson Braking Systems can accommodate extremely high torque requirements for demanding applications[/caption]

Johnson Braking Systems can accommodate extremely high torque requirements for demanding applications[/caption]

Johnson Industries Disc Calipers and Drum Brakes

Johnson designs and manufactures a range of products in house including hydraulic, pneumatic, spring-set or manually applied caliper disc brakes and brake systems for use on hoists, conveyors, propulsion systems and other rotating equipment. Johnson also produces electro-magnetic and electro-hydraulic thruster drum and disc brakes which are in service around the world on cranes, hoists and other material handling and power transmission equipment.Johnson Industries Storm and Parking Brakes

Johnson also designs and manufacture Storm and Parking brakes. Storm brake systems include automatic and manual rail clamps, rail brakes and wheel clamps. These emergency braking systems are used on cranes, stacker-reclaimers, loaders and other forms rail mounted equipment.Johnson Industries Custom Brakes and Engineering

Kor-Pak can provide you with custom engineered industrial braking systems designed specifically for your unique application. This may include assisting with the brake selection process and performing a site visit and interactive project management to design and implement the optimal and most efficient system available.About KJohnson/Elevanja

For over two decades, Kor-Pak Corporation has been a dealer/distributor for ohnson/Elevanja Industrial Braking Systems. Johnson Industries Ltd. was founded in 1966 in Richmond, B.C., and in 1993 acquired the British brake manufacturer Elevanja. Johnson Industries' strategic acquisitions, ingenuity, superior engineering, and entrepreneurial spirit has enabled it to become a premier brake manufacturer with a dominant global presence. In 2015, Elevanja will be celebrating it's 100th anniversary and Johnson Industries offers by far the most diversified and innovative brake portfolio in the marketplace. In the early 1990's, Kor-Pak founder Jim Koralik introduced Johnson electric brakes to the United States Steel Industry as the Johnson Thruster Style brakes, magnetic disc brakes, and emergency caliper brakes have become popular in EOT crane applications. Today, Kor-Pak possesses the knowledge assets and product knowledge to represent Johnson Industries Brakes in a variety of markets such as steel, mining, oil/petroleum, logging, and marine. We service clients around the world and offer 24/7 support to help our clients keep their equipment running at optimal efficiency. Contact a Kor-Pak representative to learn more about Johnson Industries brakes and allow us to serve your industrial braking system needs. [caption id="attachment_1438" align="alignright" width="231"] Johnson Braking Systems can accommodate extremely high torque requirements for demanding applications[/caption]Johnson Industries Disc Calipers and Drum Brakes

Johnson designs and manufactures a range of products in house including hydraulic, pneumatic, spring-set or manually applied caliper disc brakes and brake systems for use on hoists, conveyors, propulsion systems and other rotating equipment. Johnson also produces electro-magnetic and electro-hydraulic thruster drum and disc brakes which are in service around the world on cranes, hoists and other material handling and power transmission equipment.Johnson Industries Storm and Parking Brakes

Johnson also designs and manufacture Storm and Parking brakes. Storm brake systems include automatic and manual rail clamps, rail brakes and wheel clamps. These emergency braking systems are used on cranes, stacker-reclaimers, loaders and other forms rail mounted equipment.Johnson Industries Custom Brakes and Engineering

Kor-Pak can provide you with custom engineered industrial braking systems designed specifically for your unique application. This may include assisting with the brake selection process and performing a site visit and interactive project management to design and implement the optimal and most efficient system available. -

Magnetic Disc Brakes (6)

Magnetic Disc Brakes (6)

Kor-Pak provides a diverse selection of spring-set, magnetically released (failsafe) caliper disc brakes for Service and Emergency Duty applications. Single or dual caliper design magnetic disc brakes are available, manufactured to the highest engineering standards. [caption id="attachment_1724" align="alignright" width="350"] Dual Caliper Magnetic Disc Brake[/caption]

[caption id="attachment_2742" align="alignright" width="300"]

Dual Caliper Magnetic Disc Brake[/caption]

[caption id="attachment_2742" align="alignright" width="300"] DC Magnetic Disc Brakes on Outdoor Ship Loader/Unloader[/caption]

Features of Magnetic Disc Brakes

Failsafe: spring-set, magnetically released

Fabricated steel mechanism, all pins ground stainless steel, high temperature non-asbestos friction linings

Magnet is DC tractive type with ensapsulated coil and screw-off release nut with optional switch

Optional Limit Swtiches to monitor release/set or wear

Magnetic Disc Brakes on Outdoor Shiploader/Unloader Crane

Special materials, tests, or finishes as required

Magnetic Actuator is 100% continuously rated up to 40 degrees celsius ambient

Airgap dust and drip protected by neoprene gaitor

Terminal box IP55 enclosure

Brake release and set times are reduced by separate brake control unit to apply increased power and magnetic force during a short preset start period. Control units are enclosed ventilated drip proof IP22 for DC supplies or totally enclosed IP55 with rectifier for 1 or 3 phase AC supplies.

Applications:

Mechanical handling equipment, cranes, winches, conveyors and mills, Emergency stop brakes installed on flange of drum winding barrel.

Kor-Pak provides a diverse selection of spring-set, magnetically released (failsafe) caliper disc brakes for Service and Emergency Duty applications. Single or dual caliper design magnetic disc brakes are available, manufactured to the highest engineering standards. [caption id="attachment_1724" align="alignright" width="350"] Dual Caliper Magnetic Disc Brake[/caption] [caption id="attachment_2742" align="alignright" width="300"] DC Magnetic Disc Brakes on Outdoor Ship Loader/Unloader[/caption] Features of Magnetic Disc Brakes Failsafe: spring-set, magnetically released Fabricated steel mechanism, all pins ground stainless steel, high temperature non-asbestos friction linings Magnet is DC tractive type with ensapsulated coil and screw-off release nut with optional switch Optional Limit Swtiches to monitor release/set or wear Magnetic Disc Brakes on Outdoor Shiploader/Unloader Crane Special materials, tests, or finishes as required Magnetic Actuator is 100% continuously rated up to 40 degrees celsius ambient Airgap dust and drip protected by neoprene gaitor Terminal box IP55 enclosure Brake release and set times are reduced by separate brake control unit to apply increased power and magnetic force during a short preset start period. Control units are enclosed ventilated drip proof IP22 for DC supplies or totally enclosed IP55 with rectifier for 1 or 3 phase AC supplies. Applications: Mechanical handling equipment, cranes, winches, conveyors and mills, Emergency stop brakes installed on flange of drum winding barrel.

DC Magnetic Disc Brakes on Outdoor Ship Loader/Unloader[/caption]

Features of Magnetic Disc Brakes

Failsafe: spring-set, magnetically released

Fabricated steel mechanism, all pins ground stainless steel, high temperature non-asbestos friction linings

Magnet is DC tractive type with ensapsulated coil and screw-off release nut with optional switch

Optional Limit Swtiches to monitor release/set or wear

Magnetic Disc Brakes on Outdoor Shiploader/Unloader Crane

Special materials, tests, or finishes as required

Magnetic Actuator is 100% continuously rated up to 40 degrees celsius ambient

Airgap dust and drip protected by neoprene gaitor

Terminal box IP55 enclosure

Brake release and set times are reduced by separate brake control unit to apply increased power and magnetic force during a short preset start period. Control units are enclosed ventilated drip proof IP22 for DC supplies or totally enclosed IP55 with rectifier for 1 or 3 phase AC supplies.

Applications:

Mechanical handling equipment, cranes, winches, conveyors and mills, Emergency stop brakes installed on flange of drum winding barrel.

Kor-Pak provides a diverse selection of spring-set, magnetically released (failsafe) caliper disc brakes for Service and Emergency Duty applications. Single or dual caliper design magnetic disc brakes are available, manufactured to the highest engineering standards. [caption id="attachment_1724" align="alignright" width="350"] Dual Caliper Magnetic Disc Brake[/caption] [caption id="attachment_2742" align="alignright" width="300"] DC Magnetic Disc Brakes on Outdoor Ship Loader/Unloader[/caption] Features of Magnetic Disc Brakes Failsafe: spring-set, magnetically released Fabricated steel mechanism, all pins ground stainless steel, high temperature non-asbestos friction linings Magnet is DC tractive type with ensapsulated coil and screw-off release nut with optional switch Optional Limit Swtiches to monitor release/set or wear Magnetic Disc Brakes on Outdoor Shiploader/Unloader Crane Special materials, tests, or finishes as required Magnetic Actuator is 100% continuously rated up to 40 degrees celsius ambient Airgap dust and drip protected by neoprene gaitor Terminal box IP55 enclosure Brake release and set times are reduced by separate brake control unit to apply increased power and magnetic force during a short preset start period. Control units are enclosed ventilated drip proof IP22 for DC supplies or totally enclosed IP55 with rectifier for 1 or 3 phase AC supplies. Applications: Mechanical handling equipment, cranes, winches, conveyors and mills, Emergency stop brakes installed on flange of drum winding barrel. -

Marland Clutch (3)

Marland Clutch (3)

Kor-Pak is an authorized dealer for Marland Clutch

Marland Clutch is a world leader in the design and manufacturing of backstopping and overrunning clutches by providing quality robust designs since 1931. Marland offers a wide range of clutches with over 100 different catalog standard models, accommodating shaft sizes up to 600 mm (23.5 in.). Marland’s quality management system is certified to ISO 9001:2008. Marland has optimized Ramp and Roller technology to produce the most robust backstop and overrunning clutch designs. Marland Backstopping Clutches Marland low speed backstops are mounted on conveyor headshafts to automatically prevent any reverse rotation of

CEBMAG Backstop the headshaft or movement of the conveyor during a scheduled or un-scheduled stoppage under load. Marland high speed backstops include inner race centrifugal throughout sprag designs and fully releasable models, low speed backstops see catalog P-1469.

17 low speed models

43 high speed models

Bore sizes up to 600 mm, (23.5 in.)

Torque Ratings up to 1626000 Nm, (1,200,000)

4 Load Sharing Designs

Marland CECONs

Marland low speed backstops are mounted on conveyor headshafts to automatically prevent any reverse rotation of

CEBMAG Backstop the headshaft or movement of the conveyor during a scheduled or un-scheduled stoppage under load. Marland high speed backstops include inner race centrifugal throughout sprag designs and fully releasable models, low speed backstops see catalog P-1469.

17 low speed models

43 high speed models

Bore sizes up to 600 mm, (23.5 in.)

Torque Ratings up to 1626000 Nm, (1,200,000)

4 Load Sharing Designs

Marland CECONs

The Marland CECON family of clutches has become the industry standard for proven performance by exceeding the requirements at many global industries. The Marland CECON provides an overrunning function in a protected housing for meeting the industry demands for uninterrupted continuous dual drive applications even in extremely wet, dusty, abrasive or other adverse environments with optional complete disconnect capability, and high speed continuous operation capability, see catalog P-1471.

37 CECON models

Full Disconnect Designs, OSHA

High Speed Designs up to 12,000 RPM

Marland CEBMAGs

The Marland CEBMAG family of clutches provide protection from damage to Kilns and Kilns drives as part of an emergency drive, when the facility experiences unplanned power outages or unscheduled shut downs, see catalog P-1470.

4 CEBMAG models

Spring Applied Holding Brakes

Centrifugal Brake for speed control

Automatic auction

Marland HB Clutches: Full-Phased Cam and Rollers

Uniform Load Distribution is assured by full-phase true cylindrical rollers enclosed in a cage to act in unison on flat cam surfaces. The cage forces all the rollers to engage simultaneously, accurately maintaining their relative positions, thereby assuring that each roller will carry an equal share of the load.

Other designs utilize individual springs acting on each roller. This allows different energizing forces to cause one or more of the rollers to engage in the load carrying position prematurely, or to skew. This action will concentrate the full clutch load on one or just a few rollers causing destruction and failure of the rollers and clutch.

No Loose Parts

Rollers are contained in a spring-actuated cage. The parts will not spill or drop if field disassembly should be required.

No Backlash

When the string is lowered and the drum shaft rotates the outer race of the clutch, the spring-actuated roller cage uniformly and instantaneously moves all of the rollers into the driving position.

Long Service Life

Superior Roller Design

Related Literature:

Marland Backstops Brochure

Marland One-Way CEBMAG Backstops

Marland HB Clutches

Marland Clutch Product Line Card

Marland Clutch Product Flyer

The Marland CECON family of clutches has become the industry standard for proven performance by exceeding the requirements at many global industries. The Marland CECON provides an overrunning function in a protected housing for meeting the industry demands for uninterrupted continuous dual drive applications even in extremely wet, dusty, abrasive or other adverse environments with optional complete disconnect capability, and high speed continuous operation capability, see catalog P-1471.

37 CECON models

Full Disconnect Designs, OSHA

High Speed Designs up to 12,000 RPM

Marland CEBMAGs

The Marland CEBMAG family of clutches provide protection from damage to Kilns and Kilns drives as part of an emergency drive, when the facility experiences unplanned power outages or unscheduled shut downs, see catalog P-1470.

4 CEBMAG models

Spring Applied Holding Brakes

Centrifugal Brake for speed control

Automatic auction

Marland HB Clutches: Full-Phased Cam and Rollers

Uniform Load Distribution is assured by full-phase true cylindrical rollers enclosed in a cage to act in unison on flat cam surfaces. The cage forces all the rollers to engage simultaneously, accurately maintaining their relative positions, thereby assuring that each roller will carry an equal share of the load.

Other designs utilize individual springs acting on each roller. This allows different energizing forces to cause one or more of the rollers to engage in the load carrying position prematurely, or to skew. This action will concentrate the full clutch load on one or just a few rollers causing destruction and failure of the rollers and clutch.

No Loose Parts

Rollers are contained in a spring-actuated cage. The parts will not spill or drop if field disassembly should be required.

No Backlash

When the string is lowered and the drum shaft rotates the outer race of the clutch, the spring-actuated roller cage uniformly and instantaneously moves all of the rollers into the driving position.

Long Service Life

Superior Roller Design

Related Literature:

Marland Backstops Brochure

Marland One-Way CEBMAG Backstops

Marland HB Clutches

Marland Clutch Product Line Card

Marland Clutch Product FlyerKor-Pak is an authorized dealer for Marland Clutch

Marland Clutch is a world leader in the design and manufacturing of backstopping and overrunning clutches by providing quality robust designs since 1931. Marland offers a wide range of clutches with over 100 different catalog standard models, accommodating shaft sizes up to 600 mm (23.5 in.). Marland’s quality management system is certified to ISO 9001:2008. Marland has optimized Ramp and Roller technology to produce the most robust backstop and overrunning clutch designs. Marland Backstopping Clutches Marland low speed backstops are mounted on conveyor headshafts to automatically prevent any reverse rotation of CEBMAG Backstop the headshaft or movement of the conveyor during a scheduled or un-scheduled stoppage under load. Marland high speed backstops include inner race centrifugal throughout sprag designs and fully releasable models, low speed backstops see catalog P-1469. 17 low speed models 43 high speed models Bore sizes up to 600 mm, (23.5 in.) Torque Ratings up to 1626000 Nm, (1,200,000) 4 Load Sharing Designs Marland CECONs The Marland CECON family of clutches has become the industry standard for proven performance by exceeding the requirements at many global industries. The Marland CECON provides an overrunning function in a protected housing for meeting the industry demands for uninterrupted continuous dual drive applications even in extremely wet, dusty, abrasive or other adverse environments with optional complete disconnect capability, and high speed continuous operation capability, see catalog P-1471. 37 CECON models Full Disconnect Designs, OSHA High Speed Designs up to 12,000 RPM Marland CEBMAGs The Marland CEBMAG family of clutches provide protection from damage to Kilns and Kilns drives as part of an emergency drive, when the facility experiences unplanned power outages or unscheduled shut downs, see catalog P-1470. 4 CEBMAG models Spring Applied Holding Brakes Centrifugal Brake for speed control Automatic auction Marland HB Clutches: Full-Phased Cam and Rollers Uniform Load Distribution is assured by full-phase true cylindrical rollers enclosed in a cage to act in unison on flat cam surfaces. The cage forces all the rollers to engage simultaneously, accurately maintaining their relative positions, thereby assuring that each roller will carry an equal share of the load. Other designs utilize individual springs acting on each roller. This allows different energizing forces to cause one or more of the rollers to engage in the load carrying position prematurely, or to skew. This action will concentrate the full clutch load on one or just a few rollers causing destruction and failure of the rollers and clutch. No Loose Parts Rollers are contained in a spring-actuated cage. The parts will not spill or drop if field disassembly should be required. No Backlash When the string is lowered and the drum shaft rotates the outer race of the clutch, the spring-actuated roller cage uniformly and instantaneously moves all of the rollers into the driving position. Long Service Life Superior Roller Design Related Literature: Marland Backstops Brochure Marland One-Way CEBMAG Backstops Marland HB Clutches Marland Clutch Product Line Card Marland Clutch Product Flyer -

Pneumatic (Air) Disc Brakes (4)

Pneumatic (Air) Disc Brakes (4)

KOR-PAK AIR DISC BRAKES

Kor Pak’s pneumatic caliper brakes–also called air disc brakes–are widely used in both static and dynamic applications and span across several industries:- Industrial

- Offshore/Onshore Oil Drilling

- Marine

- Logging

- Mining

Pneumatic caliper disc brakes on a ventilated brake disc mounted on a 300,000 lb Drawworks.[/caption]

Features

Pneumatic caliper disc brakes on a ventilated brake disc mounted on a 300,000 lb Drawworks.[/caption]

Features

- MECHANISM - free-floating when set and self-centering when released

- ACTUATION - spring set / air released, air set / spring released - spring compensated

- MOUNTING - foot-mount or side-mount, actuators it her handing

- CONSTRUCTION - steel and ductile iron, or aluminum shoes, stainless steel pins standard

- CONFIGURATION - single or double actuator, offset to either side of brake disc

- LININGS - non-asbestos compositions to suit application requirements

- DISCS - solid or ventilated, carbon or stainless steel, cast iron or non-ferrous

- OPTIONS - special alloys, coatings, controls and custom mountings

- APPLICATIONS -hoists / winches, conveyers, drives, processing machines

- ENGINEERING -application and selection assistance available

KOR-PAK AIR DISC BRAKES

Kor Pak’s pneumatic caliper brakes–also called air disc brakes–are widely used in both static and dynamic applications and span across several industries:- Industrial

- Offshore/Onshore Oil Drilling

- Marine

- Logging

- Mining

- MECHANISM - free-floating when set and self-centering when released

- ACTUATION - spring set / air released, air set / spring released - spring compensated

- MOUNTING - foot-mount or side-mount, actuators it her handing

- CONSTRUCTION - steel and ductile iron, or aluminum shoes, stainless steel pins standard

- CONFIGURATION - single or double actuator, offset to either side of brake disc

- LININGS - non-asbestos compositions to suit application requirements

- DISCS - solid or ventilated, carbon or stainless steel, cast iron or non-ferrous

- OPTIONS - special alloys, coatings, controls and custom mountings

- APPLICATIONS -hoists / winches, conveyers, drives, processing machines

- ENGINEERING -application and selection assistance available

-

Sibre brakes (1)

Sibre brakes (1)

-

Stearns Brakes and Clutches (2)

Stearns Brakes and Clutches (2)

Stearns manufactures a comprehensive line of standard and special AC and DC industrial brakes and clutches.

Stearns manufactures a comprehensive line of standard and special AC and DC industrial brakes and clutches.

- Motor Mounted Brakes

- Double C-Face Coupler Brakes

- Division 1 Hazardous Location Brakes

- Division 2 Hazardous Location Brakes

- Encoder Brakes

- Stainless Steel Motor Mounted Brakes

- Stainless Steel Double C-Face Coupler Brakes

- Marine, Maritime and Navy Brakes

- Servo and Stepper Motor Brakes

- Small Gearmotor Brakes

- Small Gearmotor Brakes; Quiet Operation

- Small Gearmotor Brakes; High Cycling Brake; NEMA C-Face

- European Style Direct Acting Brakes

- European Style Direct Acting NEMA C-Face Brakes

- Direct Acting Brakes for Portal Crane Applications

- Quiet Brakes

- Caliper Brakes

- Bearing Supported Thru-Shaft Brakes

- MSHA Certified Mining Brakes

- Power On Modular Brakes

- Mechnical Lock-Out Brakes

- Heavy Duty Electromagnetic Spring Engaged Brake

Stearns manufactures a comprehensive line of standard and special AC and DC industrial brakes and clutches.- Motor Mounted Brakes

- Double C-Face Coupler Brakes

- Division 1 Hazardous Location Brakes

- Division 2 Hazardous Location Brakes

- Encoder Brakes

- Stainless Steel Motor Mounted Brakes

- Stainless Steel Double C-Face Coupler Brakes

- Marine, Maritime and Navy Brakes

- Servo and Stepper Motor Brakes

- Small Gearmotor Brakes

- Small Gearmotor Brakes; Quiet Operation

- Small Gearmotor Brakes; High Cycling Brake; NEMA C-Face

- European Style Direct Acting Brakes

- European Style Direct Acting NEMA C-Face Brakes

- Direct Acting Brakes for Portal Crane Applications

- Quiet Brakes

- Caliper Brakes

- Bearing Supported Thru-Shaft Brakes

- MSHA Certified Mining Brakes

- Power On Modular Brakes

- Mechnical Lock-Out Brakes

- Heavy Duty Electromagnetic Spring Engaged Brake

-

Svendborg Brakes (5)

Svendborg Brakes (5)

Svendborg Brakes have become a brand name in the world of industrial braking systems and they have found success on an international scale in a multitude of industries and applications. You can find Svendborg brakes on wind turbines, ball/sag mills, Drawworks, and numerous other industrial applications and their brake and accessories are engineered to extremely rigorous standards to insure long product life and outstanding performance.

[caption id="attachment_2280" align="alignright" width="300"]

Svendborg Brakes have become a brand name in the world of industrial braking systems and they have found success on an international scale in a multitude of industries and applications. You can find Svendborg brakes on wind turbines, ball/sag mills, Drawworks, and numerous other industrial applications and their brake and accessories are engineered to extremely rigorous standards to insure long product life and outstanding performance.

[caption id="attachment_2280" align="alignright" width="300"] Svendborg Hydraulic Disc Brake[/caption]

Svendborg Product Line Includes the Following:

Svendborg Hydraulic Disc Brake[/caption]

Svendborg Product Line Includes the Following:

- Hydraulic brakes with clamping forces from 500 N to 1,150,000 N

- Thruster brakes

- Hydraulic power units

- Soft braking controls

- Couplings

- Yaw systems

- Rotor locks

For more information about Svendborg products, contact a Kor-Pak representative. Click HERE for a Svendborg brochure.

Svendborg Brakes have become a brand name in the world of industrial braking systems and they have found success on an international scale in a multitude of industries and applications. You can find Svendborg brakes on wind turbines, ball/sag mills, Drawworks, and numerous other industrial applications and their brake and accessories are engineered to extremely rigorous standards to insure long product life and outstanding performance. [caption id="attachment_2280" align="alignright" width="300"] Svendborg Hydraulic Disc Brake[/caption] Svendborg Product Line Includes the Following:

For more information about Svendborg products, contact a Kor-Pak representative. Click HERE for a Svendborg brochure.

Svendborg Brakes have become a brand name in the world of industrial braking systems and they have found success on an international scale in a multitude of industries and applications. You can find Svendborg brakes on wind turbines, ball/sag mills, Drawworks, and numerous other industrial applications and their brake and accessories are engineered to extremely rigorous standards to insure long product life and outstanding performance. [caption id="attachment_2280" align="alignright" width="300"] Svendborg Hydraulic Disc Brake[/caption] Svendborg Product Line Includes the Following:- Hydraulic brakes with clamping forces from 500 N to 1,150,000 N

- Thruster brakes

- Hydraulic power units

- Soft braking controls

- Couplings

- Yaw systems

- Rotor locks

-

Thruster Disc Brakes (7)

Thruster Disc Brakes (7)

Thruster Disc Brakes are successfully used in many industries for various applications and Kor-Pak Corporation is your primary source for Thruster Drum brakes sales, service, and support.

Thruster Disc Brakes are successfully used in many industries for various applications and Kor-Pak Corporation is your primary source for Thruster Drum brakes sales, service, and support.

Spring-Applied, Fail-Safe Thruster Disc Brakes

Thruster Disc Brakes are spring-set and thruster released; the thruster is electro-hydraulic, 3-phase, including a motor and hydraulic fluid. When power is removed, the friction lining of the brake pad applies to the rotating disc which creates friction and ultimately stops the rotating disc from moving.Benefits of Thruster Disc Brakes

Thruster disc brakes possess a scalable torque tube which means that torque can be ostensibly adjusted which is ideal; for instance, as the linings gradually bed into the wheel (burnish), greater mechanical braking torque will be achieved and consequently the torque may need to be reduced. Compared to magnetic disc brakes, the brake operator can set the exact torque amount which yields more precise braking and enhanced safety. Thruster disc brakes also provide a clean, efficient, and economical package. Thrusters can accommodate high temperatures, especially with the addition of silicone fluid and high-temperature kits. Furthermore, a lowering valve/time delay can be added to the thruster to time the setting of the brake, and set/release limit switches can also be added. This is an ideal setup to be used in conjunction with variable frequency drives. External torque springs and self-adjust mechanisms for lining wear compensation are also ideal features of these brakes.Disc Brakes vs. Drum Brakes

The benefits of disc brakes is that its friction pads apply to a flat surface as opposed to a curved surface (drum brakes). Gripping onto a flat surface invariably yields greater contact and ultimately more mechanical braking torque. Also, to compensate for an uneven load of standard caliper disc brakes, a Dual-Caliper Disc Brake is also available which creates a balanced load and mitigates risks that are associated with an overhung load. [caption id="attachment_1723" align="alignright" width="300"] Thruster Released Dual Caliper Disc Brake[/caption]

Thruster Released Dual Caliper Disc Brake[/caption]

Ease of Maintenance

Thruster disc brakes consist of an electro-hydraulic actuator/thruster and the movement. Thrusters can be repaired for an affordable price and reconditioned to “like new” condition. Brake pad can be easily replaced or relined, and the movement will last long and may need to be reconditioned on occasion. Overall, thruster brakes are designed to be “hands-off” and maintenance friendly brakes, making them an ideal choice for numerous applications such as steel mills (i.e. hoist and bridge/trolley brakes in melt shops), moveable structures (bridge brakes), container crane brakes, and many more.Your Source for Electro-hydraulic (Elhy) Thrusters

Kor-Pak offers a complete line of AC and DC electro-hydraulic (Elhy) thrusters and can repair your actuator to like-new condition. Your electro-hydraulic thruster can be offered with many features such as:- Set/Release Limit Switch

- Lowering Valve (time delay)

- High-temperature package

- Explosion Proof

- Built-in heater for severely low temperatures

- Kevlar Dust Boot

- Enclosure/Brake Cover

- Reconditon thruster brake assemblies and actuators Design and engineer new thruster brake systems for custom applications Provide field service/support to help troubleshoot Provide on-site training for maintenance personnel Upgrade/retrofit existing brakes with thruster-style brakes Provide accessories: spare parts, discs, enclosures, limit switches, pads, reline brake shoes, pins, self-adjust mechanisms, actuators and many more. Integrate entire systems: thruster brakes, variable frequency drives/controls, PLC, etc.

Thruster Disc Brakes are successfully used in many industries for various applications and Kor-Pak Corporation is your primary source for Thruster Drum brakes sales, service, and support.Spring-Applied, Fail-Safe Thruster Disc Brakes

Thruster Disc Brakes are spring-set and thruster released; the thruster is electro-hydraulic, 3-phase, including a motor and hydraulic fluid. When power is removed, the friction lining of the brake pad applies to the rotating disc which creates friction and ultimately stops the rotating disc from moving.Benefits of Thruster Disc Brakes

Thruster disc brakes possess a scalable torque tube which means that torque can be ostensibly adjusted which is ideal; for instance, as the linings gradually bed into the wheel (burnish), greater mechanical braking torque will be achieved and consequently the torque may need to be reduced. Compared to magnetic disc brakes, the brake operator can set the exact torque amount which yields more precise braking and enhanced safety. Thruster disc brakes also provide a clean, efficient, and economical package. Thrusters can accommodate high temperatures, especially with the addition of silicone fluid and high-temperature kits. Furthermore, a lowering valve/time delay can be added to the thruster to time the setting of the brake, and set/release limit switches can also be added. This is an ideal setup to be used in conjunction with variable frequency drives. External torque springs and self-adjust mechanisms for lining wear compensation are also ideal features of these brakes.Disc Brakes vs. Drum Brakes

The benefits of disc brakes is that its friction pads apply to a flat surface as opposed to a curved surface (drum brakes). Gripping onto a flat surface invariably yields greater contact and ultimately more mechanical braking torque. Also, to compensate for an uneven load of standard caliper disc brakes, a Dual-Caliper Disc Brake is also available which creates a balanced load and mitigates risks that are associated with an overhung load. [caption id="attachment_1723" align="alignright" width="300"] Thruster Released Dual Caliper Disc Brake[/caption]Ease of Maintenance

Thruster disc brakes consist of an electro-hydraulic actuator/thruster and the movement. Thrusters can be repaired for an affordable price and reconditioned to “like new” condition. Brake pad can be easily replaced or relined, and the movement will last long and may need to be reconditioned on occasion. Overall, thruster brakes are designed to be “hands-off” and maintenance friendly brakes, making them an ideal choice for numerous applications such as steel mills (i.e. hoist and bridge/trolley brakes in melt shops), moveable structures (bridge brakes), container crane brakes, and many more.Your Source for Electro-hydraulic (Elhy) Thrusters

Kor-Pak offers a complete line of AC and DC electro-hydraulic (Elhy) thrusters and can repair your actuator to like-new condition. Your electro-hydraulic thruster can be offered with many features such as:- Set/Release Limit Switch

- Lowering Valve (time delay)

- High-temperature package

- Explosion Proof

- Built-in heater for severely low temperatures

- Kevlar Dust Boot

- Enclosure/Brake Cover

- Reconditon thruster brake assemblies and actuators Design and engineer new thruster brake systems for custom applications Provide field service/support to help troubleshoot Provide on-site training for maintenance personnel Upgrade/retrofit existing brakes with thruster-style brakes Provide accessories: spare parts, discs, enclosures, limit switches, pads, reline brake shoes, pins, self-adjust mechanisms, actuators and many more. Integrate entire systems: thruster brakes, variable frequency drives/controls, PLC, etc.

-

Twiflex Brakes (1)

Twiflex Brakes (1)

-

Wind Turbine Brakes (7)

Wind Turbine Brakes (7)

Wind Turbine Brake System

At Kor-Pak we are Wind Turbine Brakes System expert Contact a Kor-Pak representative today to assist you with your wind turbine braking needs. There are many aspects to windmill brakes, or wind turbine brakes and Kor-Pak covers them all. You can get expert advice on yaw brakes, blade pitch brakes, and rotor brakes as well as rotor locks, shaft locks, and linear actuators. For a reliable partner in your wind turbine brake needs, contact Kor-Pak today.

Contact a Kor-Pak representative today to assist you with your wind turbine braking needs. There are many aspects to windmill brakes, or wind turbine brakes and Kor-Pak covers them all. You can get expert advice on yaw brakes, blade pitch brakes, and rotor brakes as well as rotor locks, shaft locks, and linear actuators. For a reliable partner in your wind turbine brake needs, contact Kor-Pak today.

Yaw Brakes

A full array of caliper solutions is available from Kor-Pak to meet the yaw braking force requirements of any size wind turbine. All brake models are robust, hydraulically activated, and direct applied. Models with up to 40kN braking force, featuring two-bolt side mounting, are designed for light to medium-duty applications. We also have brake models featuring four-bolt center mounting, is ideal for use in medium sized turbines. Our base mounted caliper is designed for larger, heavy-duty turbine applications. All models of yaw brakes function as static holding brakes when the nacelle is positioned into the wind. Typically, Kor-Pak caliper brakes may act directly on the yaw ring or Matrix plate-type brakes are mounted on the non-driving end of the yaw motors. More for Yaw Brake ProductsRotor Brakes

[caption id="attachment_3988" align="alignright" width="300"] Windmill Rotor Brakes[/caption]

Kor-Pak rotor brakes are in operation today on hundreds of wind turbines around the world. All models are fully assembled,provide high levels of reliability,easy electronic monitoring and maintenance,and are available with organic or metallic linings. Friction liners are carefully sized to ensure adequate heat dissipation during an emergency stop, with even pressure distribution across pad surfaces.

Models are offered in a range of braking forces from 100N to 1MN to meet the braking torque requirements of the most common turbine sizes. Rotor brake models are available as both standard and floating models. Floating, single-sided brakes are mounted on sliding bushings to save space on the installation.

Our spring-applied, hydraulically-released, caliper brakes are typically mounted to a turbine's main rotor shaft, between the gearbox and the generator, and used primarily as safety brakes during emergency stops under high wind conditions. All units are engineered to handle the large output torque reduction generated by the very high ratios found in wind turbine gearboxes.

Windmill Rotor Brakes[/caption]

Kor-Pak rotor brakes are in operation today on hundreds of wind turbines around the world. All models are fully assembled,provide high levels of reliability,easy electronic monitoring and maintenance,and are available with organic or metallic linings. Friction liners are carefully sized to ensure adequate heat dissipation during an emergency stop, with even pressure distribution across pad surfaces.

Models are offered in a range of braking forces from 100N to 1MN to meet the braking torque requirements of the most common turbine sizes. Rotor brake models are available as both standard and floating models. Floating, single-sided brakes are mounted on sliding bushings to save space on the installation.

Our spring-applied, hydraulically-released, caliper brakes are typically mounted to a turbine's main rotor shaft, between the gearbox and the generator, and used primarily as safety brakes during emergency stops under high wind conditions. All units are engineered to handle the large output torque reduction generated by the very high ratios found in wind turbine gearboxes.

Rotor Locks

Rotor locks are used in the wind turbine industry and are typically mounted to the turbine´s main rotor shaft, between gearbox and generator. A rotor brake is primarily intended for use as safety brake during emergency stops under high wind conditions. The rotor lock is activated by running the lock bolt into the lock disc using hydraulic power; a "locked" signal is then transmitted to the control system. Our rotor lock units are engineered to handle the large output torque generated by the high ratios found in wind turbine gearboxes.Key benefits of our rotor locks for wind turbines:

- Control system notifies of turbine failure or breakdown

- Failure notice monitored by main Service Department

- Local service engineer dispatched to the site immediately, where decision is taken to put the turbine into Rotor Lock Mode - saving valuable service time

- Rotor Lock Mode activated by remote control

- Turbine rotor brought to a full stop by aerodynamic and mechanical brakes

Access Hatch Linear Actuators

Our broad range of standard actuators can be custom-configured to meet specific applications including special pin to pin and stroke lengths, special end fittings, mounting brackets, paints, and lead wire lengths. Load capacity up to 12,500 Nm. The rugged B-Track linear actuators are completely sealed and designed for tough, high load applications. They incorporate high strength, high quality components to provide years of trouble-free performance in harsh environments. Models feature a ball nut screw drive with integral load holding brake and overload clutch. Efficient power use, compact package size, excellent corrosion protection, rugged spur gearing, synthetic lubricants and high performance motors provide maximum capability and value.- Stroke lengths from 2 inches to 24 inches (50 mm to 610 mm)

- Travel speeds up to 2.7 in./sec (68.58 mm/sec)

- AC or DC configuration

- Optional limit switches: fixed or customer adjustable

Blade Pitch Brakes

Our Blade Pitch Brakes are electrically-released, spring-set brakes that offer a high-performance, cost-effective solution for applications that require both “static” holding power and the ability to withstand high inertia dynamic stops in an emergency situation. Each of the three blades on a typical turbine can be individually positioned (rotated) to achieve maximum efficiency while operating in changing wind conditions. The electromagnetic brake is mounted outboard of an inductive encoder which is mounted to the back of a motor to position the blades to the proper pitch. In normal use, the brake functions as a static brake to hold the blades from rotating in a power-off situation, during routine maintenance or for other reasons. Our blade pitch brakes also offer the advantage of being a one-piece design, fully-enclosed and painted to withstand extreme environmental conditions (salt-spray, condensation, water, etc.).

Shaft Locking Devices

Our hydraulic (HLD) and mechanical (MLD) locking devices are custom engineered for a lightweight,high torque connection between the turbine main shaft and gearbox. Units are domestically manufactured to provide years of trouble-free service in wind turbines rated up to 3 MW. The greatest advantage of the HLD (Hydraulic Locking Devices) is the significant time savings during installation. With larger diameters,such as 20.8 in. (530 mm),the HLD can be tensioned within only a few minutes, compared to several hours required for a mechanical locking device. The hydraulic pump required for assembly can be a stationary unit,but the use of a hydraulic hand pump is also possible for tensioning at difficult-to-reach places such as the turret of a wind turbine. The MLD (Mechanical Locking Device) units eliminate the need for keyways or splines,provide unlimited shaft positioning,and feature zero backlash,reduced shaft stress,and high contact pressure for greater torque. The MLD series has the ability to fit into smaller installations while only requiring standard tools to assemble. All units are pre-assembled,ready to install. Torque range up to 4,425,372 ft.lbs. (6,000 kNm). A wide range of possibilities is available with outer diameters up to 57.1 in (1,450 mm),and shaft diameters up to 29.5 in. (750 mm). Ameridrives is also offering HTS (Hydraulic Tensioner Systems). These products are all custom engineered for the customer. Modular,light weight design allows for versatile application. HTS can reduce the installation time of mechanical locking devices 80-90%.

Wind Turbine Brake Pads

Kor-Pak provide customers with high quality OEM and after marketing brake pads for wind turbine brakes. In addition to the brake pads, we carry brake pad assembly for Svendborg BSFI 200 Hydraulic Brake. Contact us to meet any friction material need.Wind Turbine Brake System

At Kor-Pak we are Wind Turbine Brakes System expert Contact a Kor-Pak representative today to assist you with your wind turbine braking needs. There are many aspects to windmill brakes, or wind turbine brakes and Kor-Pak covers them all. You can get expert advice on yaw brakes, blade pitch brakes, and rotor brakes as well as rotor locks, shaft locks, and linear actuators. For a reliable partner in your wind turbine brake needs, contact Kor-Pak today.Yaw Brakes

A full array of caliper solutions is available from Kor-Pak to meet the yaw braking force requirements of any size wind turbine. All brake models are robust, hydraulically activated, and direct applied. Models with up to 40kN braking force, featuring two-bolt side mounting, are designed for light to medium-duty applications. We also have brake models featuring four-bolt center mounting, is ideal for use in medium sized turbines. Our base mounted caliper is designed for larger, heavy-duty turbine applications. All models of yaw brakes function as static holding brakes when the nacelle is positioned into the wind. Typically, Kor-Pak caliper brakes may act directly on the yaw ring or Matrix plate-type brakes are mounted on the non-driving end of the yaw motors. More for Yaw Brake ProductsRotor Brakes

[caption id="attachment_3988" align="alignright" width="300"] Windmill Rotor Brakes[/caption] Kor-Pak rotor brakes are in operation today on hundreds of wind turbines around the world. All models are fully assembled,provide high levels of reliability,easy electronic monitoring and maintenance,and are available with organic or metallic linings. Friction liners are carefully sized to ensure adequate heat dissipation during an emergency stop, with even pressure distribution across pad surfaces. Models are offered in a range of braking forces from 100N to 1MN to meet the braking torque requirements of the most common turbine sizes. Rotor brake models are available as both standard and floating models. Floating, single-sided brakes are mounted on sliding bushings to save space on the installation. Our spring-applied, hydraulically-released, caliper brakes are typically mounted to a turbine's main rotor shaft, between the gearbox and the generator, and used primarily as safety brakes during emergency stops under high wind conditions. All units are engineered to handle the large output torque reduction generated by the very high ratios found in wind turbine gearboxes.Rotor Locks

Rotor locks are used in the wind turbine industry and are typically mounted to the turbine´s main rotor shaft, between gearbox and generator. A rotor brake is primarily intended for use as safety brake during emergency stops under high wind conditions. The rotor lock is activated by running the lock bolt into the lock disc using hydraulic power; a "locked" signal is then transmitted to the control system. Our rotor lock units are engineered to handle the large output torque generated by the high ratios found in wind turbine gearboxes.Key benefits of our rotor locks for wind turbines:

- Control system notifies of turbine failure or breakdown

- Failure notice monitored by main Service Department

- Local service engineer dispatched to the site immediately, where decision is taken to put the turbine into Rotor Lock Mode - saving valuable service time

- Rotor Lock Mode activated by remote control

- Turbine rotor brought to a full stop by aerodynamic and mechanical brakes

Access Hatch Linear Actuators

Our broad range of standard actuators can be custom-configured to meet specific applications including special pin to pin and stroke lengths, special end fittings, mounting brackets, paints, and lead wire lengths. Load capacity up to 12,500 Nm. The rugged B-Track linear actuators are completely sealed and designed for tough, high load applications. They incorporate high strength, high quality components to provide years of trouble-free performance in harsh environments. Models feature a ball nut screw drive with integral load holding brake and overload clutch. Efficient power use, compact package size, excellent corrosion protection, rugged spur gearing, synthetic lubricants and high performance motors provide maximum capability and value.- Stroke lengths from 2 inches to 24 inches (50 mm to 610 mm)

- Travel speeds up to 2.7 in./sec (68.58 mm/sec)

- AC or DC configuration

- Optional limit switches: fixed or customer adjustable

Blade Pitch Brakes

Our Blade Pitch Brakes are electrically-released, spring-set brakes that offer a high-performance, cost-effective solution for applications that require both “static” holding power and the ability to withstand high inertia dynamic stops in an emergency situation. Each of the three blades on a typical turbine can be individually positioned (rotated) to achieve maximum efficiency while operating in changing wind conditions. The electromagnetic brake is mounted outboard of an inductive encoder which is mounted to the back of a motor to position the blades to the proper pitch. In normal use, the brake functions as a static brake to hold the blades from rotating in a power-off situation, during routine maintenance or for other reasons. Our blade pitch brakes also offer the advantage of being a one-piece design, fully-enclosed and painted to withstand extreme environmental conditions (salt-spray, condensation, water, etc.).Shaft Locking Devices

Our hydraulic (HLD) and mechanical (MLD) locking devices are custom engineered for a lightweight,high torque connection between the turbine main shaft and gearbox. Units are domestically manufactured to provide years of trouble-free service in wind turbines rated up to 3 MW. The greatest advantage of the HLD (Hydraulic Locking Devices) is the significant time savings during installation. With larger diameters,such as 20.8 in. (530 mm),the HLD can be tensioned within only a few minutes, compared to several hours required for a mechanical locking device. The hydraulic pump required for assembly can be a stationary unit,but the use of a hydraulic hand pump is also possible for tensioning at difficult-to-reach places such as the turret of a wind turbine. The MLD (Mechanical Locking Device) units eliminate the need for keyways or splines,provide unlimited shaft positioning,and feature zero backlash,reduced shaft stress,and high contact pressure for greater torque. The MLD series has the ability to fit into smaller installations while only requiring standard tools to assemble. All units are pre-assembled,ready to install. Torque range up to 4,425,372 ft.lbs. (6,000 kNm). A wide range of possibilities is available with outer diameters up to 57.1 in (1,450 mm),and shaft diameters up to 29.5 in. (750 mm). Ameridrives is also offering HTS (Hydraulic Tensioner Systems). These products are all custom engineered for the customer. Modular,light weight design allows for versatile application. HTS can reduce the installation time of mechanical locking devices 80-90%.Wind Turbine Brake Pads

Kor-Pak provide customers with high quality OEM and after marketing brake pads for wind turbine brakes. In addition to the brake pads, we carry brake pad assembly for Svendborg BSFI 200 Hydraulic Brake. Contact us to meet any friction material need. -

Dual Caliper Balanced Load Dis (2)..

Dual Caliper Balanced Load Disc Brakes (2)

Dual Caliper Balanced Load Disc Brakes:

Impeccable Balance

[caption id="attachment_1723" align="alignright" width="300"] Thruster Released Dual Caliper Disc Brake[/caption]

Thruster Released Dual Caliper Disc Brake[/caption]

Kor-Pak’s Dual Caliper Disc Brakes blend best of both worlds: the balanced torque of a drum brake and the even contact of a disc brake. This is achieved by featuring twin calipers which interface with the disc at symmetrical points which mitigates the risks associated with tangential forces occurring at uneven contact points.

Features and Benefits of the Dual Caliper Disc Brake:

- Safe in the Event of Power Loss: Spring-set, Electro-Hydraulic

- Spring-Set, Thruster Released Dual Caliper Disc Brake

- Thruster or Magnet Released. In other words, when power is removed, the brake sets which prevents the load from falling

- Greater coefficient of friction achieved which yields greater torque

- Reduced size of the disc

- Reduced Costs of the Gear Box due to reduced distance between input and output shaft.

- Self-adjuster for lining wear compensation

- Series or Shunt Wound Coil (for DC Magnet Brakes)

- Zero Overhung Load/Balanced Torque means a lesser propensity for the shaft to twist and potentially break. This means a lesser likelihood of a catastrophic failure from occurring.

- Sliding Torque Scale (for thruster brake)

- Options: Lowering Valve, Release Limit Switch, High-Temperature Oil

- Offered as drop-in to AISE Standard Dimensions

- Discs, Drums, Couplings, and accessories available for complete drop-in package

Unequivocally, the benefits of a Dual Caliper Disc Brake exceed the costs.

To learn more about these brakes, please contact a Kor-Pak representative who will be delighted to tell you more about what these fine braking systems have to offer.

Dual Caliper Balanced Load Disc Brakes:

Impeccable Balance

[caption id="attachment_1723" align="alignright" width="300"] Thruster Released Dual Caliper Disc Brake[/caption]Kor-Pak’s Dual Caliper Disc Brakes blend best of both worlds: the balanced torque of a drum brake and the even contact of a disc brake. This is achieved by featuring twin calipers which interface with the disc at symmetrical points which mitigates the risks associated with tangential forces occurring at uneven contact points.

Features and Benefits of the Dual Caliper Disc Brake:

- Safe in the Event of Power Loss: Spring-set, Electro-Hydraulic

- Spring-Set, Thruster Released Dual Caliper Disc Brake

- Thruster or Magnet Released. In other words, when power is removed, the brake sets which prevents the load from falling

- Greater coefficient of friction achieved which yields greater torque

- Reduced size of the disc

- Reduced Costs of the Gear Box due to reduced distance between input and output shaft.

- Self-adjuster for lining wear compensation

- Series or Shunt Wound Coil (for DC Magnet Brakes)

- Zero Overhung Load/Balanced Torque means a lesser propensity for the shaft to twist and potentially break. This means a lesser likelihood of a catastrophic failure from occurring.

- Sliding Torque Scale (for thruster brake)

- Options: Lowering Valve, Release Limit Switch, High-Temperature Oil

- Offered as drop-in to AISE Standard Dimensions

- Discs, Drums, Couplings, and accessories available for complete drop-in package

Unequivocally, the benefits of a Dual Caliper Disc Brake exceed the costs.

To learn more about these brakes, please contact a Kor-Pak representative who will be delighted to tell you more about what these fine braking systems have to offer.

-

Drum Brakes (38)

Drum Brakes (38)

Kor-Pak can supply various styles of drum brakes with electro hydraulic and magnetic actuators in all AISE dimensions, and we can also provide custom drum brakes tailored specifically to your unique application. We can also provide all spare products and accompanying items such as brake drums, shoes, thrusters, coils (both shunt and series wound), controllers, and spare parts. [caption id="attachment_885" align="alignright" width="300"]

18" Thruster Drum Brake[/caption]

18" Thruster Drum Brake[/caption]

- DC Magnetic Drum Brakes

- Thruster Drum Brakes

- DC Solenoid Magnetic Drum Brakes

- Three Phase Magnetic AC Drum Brakes

- Hydraulic Drum/Shoe brakes

- Handwheel Drum Brakes

Kor-Pak can supply various styles of drum brakes with electro hydraulic and magnetic actuators in all AISE dimensions, and we can also provide custom drum brakes tailored specifically to your unique application. We can also provide all spare products and accompanying items such as brake drums, shoes, thrusters, coils (both shunt and series wound), controllers, and spare parts. [caption id="attachment_885" align="alignright" width="300"] 18" Thruster Drum Brake[/caption]- DC Magnetic Drum Brakes

- Thruster Drum Brakes

- DC Solenoid Magnetic Drum Brakes

- Three Phase Magnetic AC Drum Brakes

- Hydraulic Drum/Shoe brakes

- Handwheel Drum Brakes

- Mondel Brakes Application Bulletin

-

Storm and Parking Brakes (17)

Storm and Parking Brakes (17)

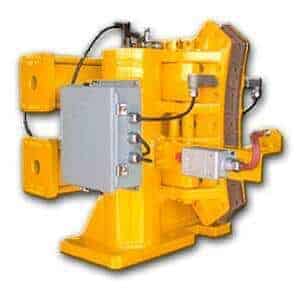

Storm Brakes

Our innovative and diverse selection of storm and rail brakes have helped industries persevere throughout harsh and demanding environments. Whether it be intense winds, seismic activity, or bracing your container when incurring heavy loads, Kor-Pak’s Storm Brakes will enable you to overcome these obstacles and achieve your industry-specific goals.Rail Clamps

Find more information about oure Rail Head Clamps. Contact us with any questions or to place an order.

- Spring force toggle compensated mechanism

- Offered with various mounting options: Truck, Sill-Beam, Flange

- Actuation is automatic spring-set, hydraulic pressure released

- Applications include ships, cranes, stackers, reclaimers, and trippers

- Electro-mechanical rail clamps available (non fail-safe)

Rail Head Friction

Parking Brakes

- Direct-acting shoe bearing on top of rail head mechanism

- Actuation is spring-set, hydraulic pressure released

- Sill-mounted mounting with shims and plated emergency release bolts

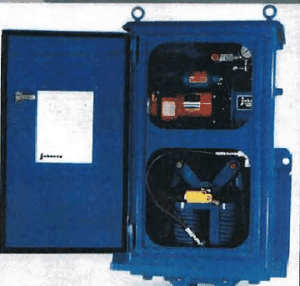

[caption id="attachment_2120" align="alignright" width="300"]

Self-Contained Storm Brake with Integral Power Unit[/caption]

Self-Contained Storm Brake with Integral Power Unit[/caption] - Hydraulic power units available to suit all operating requirements

- Used on cranes, shiploaders, stackers, reclaimers, and various other industrial applications

Wheel Clamps and Brakes

[caption id="attachment_7172" align="alignright" width="356"]

Tripper Rail Clamp[/caption]

Tripper Rail Clamp[/caption]

- Includes Wheel Gripper System

Tripper Rail Clamps

Railcar Brakes for Mining Applications

Rail Head Brakes

A similar style of Storm Brake, Rail Brakes incorporate a hardened tool steel shoe, which is applied directly to the top of a rail head by spring force. Rail brakes are sill-mounted with shims and plated emergency release bolts. The spring stack can be varied to deliver the required holding force. Lubrication points are provided at the head/shoe mating surfaces. Features and options include a release indicating/interlock limit switch, special alloys, coatings and custom mountings.Kor-Pak Rail Clamp Brochure

Storm Brakes

Our innovative and diverse selection of storm and rail brakes have helped industries persevere throughout harsh and demanding environments. Whether it be intense winds, seismic activity, or bracing your container when incurring heavy loads, Kor-Pak’s Storm Brakes will enable you to overcome these obstacles and achieve your industry-specific goals.Rail Clamps