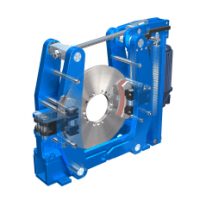

Thruster Disc Brakes

Thruster Disc Brakes are successfully used in many industries for various applications and Kor-Pak Corporation is your primary source for Thruster Drum brakes sales, service, and support.

Thruster Disc Brakes are successfully used in many industries for various applications and Kor-Pak Corporation is your primary source for Thruster Drum brakes sales, service, and support.

Spring-Applied, Fail-Safe Thruster Disc Brakes

Thruster Disc Brakes are spring-set and thruster released; the thruster is electro-hydraulic, 3-phase, including a motor and hydraulic fluid. When power is removed, the friction lining of the brake pad applies to the rotating disc which creates friction and ultimately stops the rotating disc from moving.

Benefits of Thruster Disc Brakes

Thruster disc brakes possess a scalable torque tube which means that torque can be ostensibly adjusted which is ideal; for instance, as the linings gradually bed into the wheel (burnish), greater mechanical braking torque will be achieved and consequently the torque may need to be reduced. Compared to magnetic disc brakes, the brake operator can set the exact torque amount which yields more precise braking and enhanced safety.

Thruster disc brakes also provide a clean, efficient, and economical package. Thrusters can accommodate high temperatures, especially with the addition of silicone fluid and high-temperature kits. Furthermore, a lowering valve/time delay can be added to the thruster to time the setting of the brake, and set/release limit switches can also be added. This is an ideal setup to be used in conjunction with variable frequency drives. External torque springs and self-adjust mechanisms for lining wear compensation are also ideal features of these brakes.

Disc Brakes vs. Drum Brakes

The benefits of disc brakes is that its friction pads apply to a flat surface as opposed to a curved surface (drum brakes). Gripping onto a flat surface invariably yields greater contact and ultimately more mechanical braking torque. Also, to compensate

for an uneven load of standard caliper disc brakes, a Dual-Caliper Disc Brake is also available which creates a balanced load and mitigates risks that are associated with an overhung load.

Thruster Released Dual Caliper Disc Brake

Ease of Maintenance

Thruster disc brakes consist of an electro-hydraulic actuator/thruster and the movement. Thrusters can be repaired for an affordable price and reconditioned to “like new” condition. Brake pad can be easily replaced or relined, and the movement will last long and may need to be reconditioned on occasion. Overall, thruster brakes are designed to be “hands-off” and maintenance friendly brakes, making them an ideal choice for numerous applications such as steel mills (i.e. hoist and bridge/trolley brakes in melt shops), moveable structures (bridge brakes), container crane brakes, and many more.

Your Source for Electro-hydraulic (Elhy) Thrusters

Kor-Pak offers a complete line of AC and DC electro-hydraulic (Elhy) thrusters and can repair your actuator to like-new condition. Your electro-hydraulic thruster can be offered with many features such as:

- Set/Release Limit Switch

- Lowering Valve (time delay)

- High-temperature package

- Explosion Proof

- Built-in heater for severely low temperatures

- Kevlar Dust Boot

- Enclosure/Brake Cover

Kor-Pak Can Do It All

- Reconditon thruster brake assemblies and actuators

Design and engineer new thruster brake systems for custom applications

Provide field service/support to help troubleshoot

Provide on-site training for maintenance personnel

Upgrade/retrofit existing brakes with thruster-style brakes

Provide accessories: spare parts, discs, enclosures, limit switches, pads, reline brake shoes, pins, self-adjust mechanisms, actuators and many more.

Integrate entire systems: thruster brakes, variable frequency drives/controls, PLC, etc.

Showing all 7 results

-

HUAWU Brakes

HUAWU Brakes

Read more -

Johnson Industries TBC1924-EJ121/6L..

Johnson Industries TBC1924-EJ121/6LO Disc Brake (balanced load)

Read more -

Pintsch Bubenzer Brakes

Pintsch Bubenzer Brakes

Read more -

Pintsch Bubenzer SB28 ED201/60 Thru..

Pintsch Bubenzer SB28 ED201/60 Thruster Disc Brake

Read more -

Pintsch Bubenzer SB38 Disc Brake

Pintsch Bubenzer SB38 Disc Brake

Read more -

SIBRE Brakes

SIBRE Brakes

View products -

SIBRE TEXU Twin Caliper Disc Brake

SIBRE TEXU Twin Caliper Disc Brake

Read more