Hydraulic Caliper Disc Brakes

KOR-PAK HYDRAULIC CALIPER DISC BRAKES

Kor-Pak provides an extensive portfolio of spring-set, hydraulic released caliper disc brakes that can accommodate extremely high torque requirements.

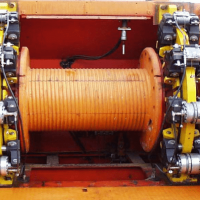

Our brakes are used in applications around the world including: drawworks, grinding mills, conveyors, crane/hoist, winches, ship loaders/unloaders, and many others. Our lever and direct-acting caliper disc brakes contain features that create long life and the capability of withstanding harsh environmental conditions. Whether it be designing brakes for a new application or retrofitting an existing one, Kor-Pak will meet your needs and provide you with hydraulic disc brakes that offer safe and reliable braking.

Lever Actuated Hydraulic Caliper Disc Brakes:

– Spring Set / Hydraulic Released Disc Brakes

– Hydraulic set / Spring Released Disc Brakes

- MECHANISM – free-floating when set and self-centering

when released - ACTUATION – spring set / hydraulic released, hydraulic set /

spring released – spring compensated - MOUNTING – foot-mount or side-mount, actuators either

handing - CONSTRUCTION – steel and ductile iron, or aluminum

shoes, stainless steel pins standard - CONFIGURATION – single or double actuator, offset to

either side of brake disc - LININGS – non-asbestos compositions to suit application

requirements - DISCS – solid or ventilated, carbon or stainless steel, cast

iron or non-ferrous - OPTIONS – special alloys, coatings, controls and custom

mountings - APPLICATIONS -hoists / winches, conveyers, drives,

processing machines - ENGINEERING -application and selection assistance

available

Direct Spring Acting Hydraulic Disc Brakes:

Fast acting, requiring little maintenance and almost no lubrication, accommodating several applications and can endure harsh operating environments. Used successfully for many applications such as emergency braking systems for Container Cranes and Ladle Cranes, Drawworks, Conveyors, and Logging Mills.

Direct Spring Brake Features:

- Spring set, hydraulic pressure release

- Self-contained removable actuators

- Many spring stack options

- Stroke / wear adjustment

- Spring caging feature

- Hydraulic pressure isolated from disc

- Actuator manual release / retraction

- Fixed assemblies with opposing actuators

- Floating assemblies with low friction float bearings

- Floating assemblies with single or opposing actuators

- Narrow profile with actuators on one side

- Single and multiple actuator assemblies

- Optional bases for fixed and floating assemblies

- Optional release and wear proximity – switches

- Flow through actuators – better oil filtering

Showing 1–16 of 17 results

-

28HHH Johnson Industries Hydraulic ..

28HHH Johnson Industries Hydraulic Disc Brakes

Read more -

3836HX Johnson Industries Hydrauli..

3836HX Johnson Industries Hydraulic Disc Brakes

Read more -

58HHH Johnson Industries Hydraulic ..

58HHH Johnson Industries Hydraulic Disc Brakes

Read more -

6800HHH Drawworks Disc Brake

6800HHH Drawworks Disc Brake

Read more -

74HHH Johnson Industries Hydraulic ..

74HHH Johnson Industries Hydraulic Disc Brakes

Read more -

7600 Series Johnson Industries Hydr..

7600 Series Johnson Industries Hydraulic Disc Brakes

Read more -

Direct Acting Spring Disc Brakes

Direct Acting Spring Disc Brakes

Read more -

DS1040-08 Johnson Industries Direct..

DS1040-08 Johnson Industries Direct Acting Spring Hydraulic Disc Brakes

Read more -

JC50D Drawworks Caliper Disc Brakes

JC50D Drawworks Caliper Disc Brakes

Read more -

Johnson Industries DS1050-10 Hydrau..

Johnson Industries DS1050-10 Hydraulic Caliper Disc Brake

Read more -

Johnson Industries/Elevanja 68HHH C..

Johnson Industries/Elevanja 68HHH Caliper Disc Brake

Read more -

Kobelt Brakes

Kobelt Brakes

Read more -

Pintsch Bubenzer Brakes

Pintsch Bubenzer Brakes

Read more -

SIBRE Brakes

SIBRE Brakes

View products -

SIBRE SHI 251 Hydraulic Caliper Bra..

SIBRE SHI 251 Hydraulic Caliper Brake

Read more -

Stromag Brakes

Stromag Brakes

Read more