Industrial Brakes & Clutches

Showing 49–64 of 120 results

-

GE IC9528A102 DC Magnetic Shoe Brak..

GE IC9528A102 DC Magnetic Shoe Brake Assembly

Read more -

Hillmar Rail Clamps

Hillmar Rail Clamps

Read more -

HUAWU Brakes

HUAWU Brakes

Read more -

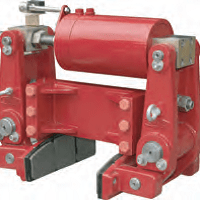

Hydraulic Wheel Brakes

Hydraulic Wheel Brakes

Read more -

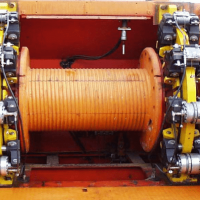

JC50D Drawworks Caliper Disc Brakes

JC50D Drawworks Caliper Disc Brakes

Read more -

Johnson 19″ SMLB Thruster Dr..

Johnson 19″ SMLB Thruster Drum Brake

Read more -

Johnson CX40 Magnetic Disc Brake Sp..

Johnson CX40 Magnetic Disc Brake Spare Parts

Read more -

Johnson Industries Brakes

Johnson Industries Brakes

Read more -

Johnson Industries CX Emergency Sto..

Johnson Industries CX Emergency Stop Duty Magnetic Disc Brake

Read more -

Johnson Industries DS1050-10 Hydrau..

Johnson Industries DS1050-10 Hydraulic Caliper Disc Brake

Read more -

Johnson Industries RB Series Rail B..

Johnson Industries RB Series Rail Brake

Read more -

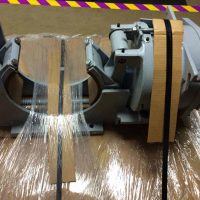

Johnson Industries SMLBW18-EJ121/06..

Johnson Industries SMLBW18-EJ121/06 Thruster Drum Brake Assembly

Read more -

Johnson Industries STC012 Rail Clam..

Johnson Industries STC012 Rail Clamp

Read more -

Johnson Industries TBC1924-EJ121/6L..

Johnson Industries TBC1924-EJ121/6LO Disc Brake (balanced load)

Read more -

Johnson Industries/Elevanja 68HHH C..

Johnson Industries/Elevanja 68HHH Caliper Disc Brake

Read more -

Kobelt Brakes

Kobelt Brakes

Read more