Description

Ringspann Clamping Systems for Torque Motors

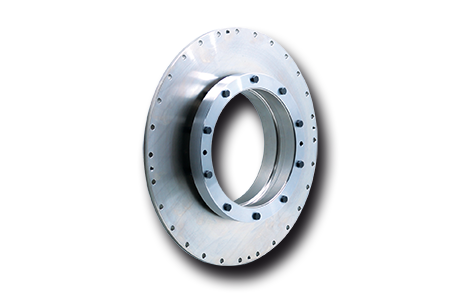

Clamping Systems RTM 601

-

-

Clamping Systems RTM 601

for integrated torque motors

for mounting and centring rotorsFeatures

- Provides a mechanical connection and centring between rotor and machine shaft

- Backlash free, torsion-proof transmission of torque generated by the torque motor

- High true run accuracy between rotor and a stator mounted on the machine

- Low contact pressures exerted on machine shafts or hollow shafts

- Taper Collet chemically nickel-coated to prevent fretting corrosion

- Easily removable clamping element, even after long periods of operation

Catalogue Shaft-Hub-Connections

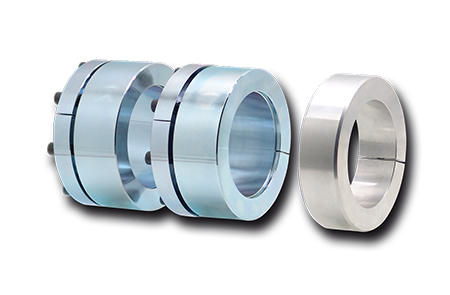

Clamping Systems RTM 607

-

-

Clamping Systems RTM 607

for SIEMENS complete torque motors 1FW3

for mounting and centring complete torque motorsFeatures

- Provides a mechanical connection, support and centring between rotor and machine shaft

- Backlash free, torsion-proof transmission of torque generated by the torque motor

- High true running accuracy

- Optimally configured contact pressure prevents undesirable deformation of hollow machine shafts

- Taper Collet chemically nickel-coated to prevent fretting corrosion

- Easily removable Cone Clamping Element, even after long periods of operation

- Centring bush can be mounted from the B-side of the torque motor

-

Product information

Clamping Systems RTM 608.1 and RTM 608.2

-

-

Clamping Systems RTM 608.1 and RTM 608.2

for complete torque motors

for mounting and centring complete torque motorsFeatures

- Provides a mechanical connection, support and centring between rotor and machine shaft

- Backlash free, torsion-proof transmission of torque generated by the torque motor

- High true running accuracy

- For inexpensive clamping on solid shafts

- Easily removable Cone Clamping Element, even after long periods of operation

-

Product information

Clamping Systems RTM 134.1 and RTM 134.2

-

-

Clamping Systems RTM 134.1 and RTM 134.2

for complete torque motors

for mounting and centring complete torque motorsFeatures

- Provides a mechanical connection and centring between rotor and machine shaft. Support is provided by additional centring ring

- Backlash free, torsion-proof transmission of torque generated by the torque motor

- High true running accuracy

- Optimally configured contact pressure prevents undesirable deformation of the hollow rotor shaft of the torque motor and the hollow machine shaft

- Taper Collet galvanized and blue-chromed to prevent fretting corrosion

- Easily removable Cone Clamping Elements, even after long periods of operation

- Cone Clamping Elements can be mounted from the B-side of the torque motor

-

Product information

-

-