Get the right Stromag Clutch

Stromag Clutches are engineered to take the stresses that come with industrial applications and drivetrains. Through unique designs, every Stromag clutch offers reduced mounting space while raising the power density. If you are unsure which Stromag Clutch is right for your application, contact Kor-Pak and we will ensure you receive the right clutch to maximize the efficiency of your industrial process.

Electrical Industrial Clutches

Friction Clutches MFT

Delivering a Torque of 7-7800 Nm, the friction clutches from Stromag are electrically operated to provide clean and simple actuation. These clutches are built for high switching frequency and short switching times.Small dimensions | High switching frequency | Short switching times | Fixed and wear free power transmission without slip ring | Diaphragm technology for torque transmission free from backlash and disengagement free from residual torque | Low idling torque | Diaphragms for low axial restoring forces | Steel-steel friction combination, hardened for high wear resistance |

Pole-Face Friction Clutches MWU

Single-disc Clutches

MEA/MBA electromagnetic single disc clutches provide high work capacity to accelerate large flywheel masses without backlash. This makes them ideal for general and heavy machinery, rolling mill plant; mining, paper, mixing machinery; high power diesel applications.Torque 210-12,000 Nm | Outer diameter 255-880 mm with or without slip rings | Max work capacity | Only one friction surface | No residual torque in the opened state | Free from backlash | For shaft separating clutches, low axial forces with engaged clutch | Simple maintenance work |

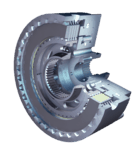

Multi-disc Clutches eke

Braking torque 12.5-10,000 Nm (higher on request) | Wet or dry running possible with suitable friction disc combinations | Outer diameter 95-560 mm | Small dimensions | High torques | High work capacity | Free from axial forces | With or without slip ring(s) | Maintenance free or low maintenance, simple handling | Multiple friction faces | Low residual torque in open condition | Slight gear backlash in the discs |

Stromag toothed clutches ZBA

Braking torque 20-100,000 Nm (higher on request) | Wet or dry running | Outer diameter 60-850 mm | Minimum dimensions with maximum torques | Torque transmission via form-fit crown gears | Engagement only at zero speed | No residual torque in open condition | Slight gear backlash in the guide toothing | Zero backlash also possible (series specific) | Shaft-hub clutch free from axial forces | For shaft separating clutches, low axial forces with engaged clutch | With or without slip ring(s) | Maintenance free or low maintenance | Simple handling |

hydraulic/pneumatic Clutches

Dry running diaphragm clutch KHM

High torques and high heat capacity are design for accelerating large mass inertias. Designed for the rugged environment off-road equipment faces, they install easily, take little switching energy, and generate very little residual friction when idle.Powerful | Compact | Low wear and noise levels | Robust | Energy efficient | Extremely easy to install |

Dry running multi-disc clutch

KMK hydraulic clutches are designed to deliver higher torque in per unit of mounting space with greater control of activation.Low maintenance | Slight gear backlash in the discs | Operating excess pressure 5.5 bar | Torque 120-60,000 Nm (higher on request) | Wet or dry running possible with suitable friction disc combination | Outer diameter 114-640 mm | Multiple friction surfaces, low residual torque in open condition | Small dimensions | High torques | High work capacity |

Wet running multi-disc clutches

All torques realisable | Excellent torque to weight ratio | Low mass moment of inertia | High thermal load capacity | Switching heat dissipated by internal oil cooling | Long service life of the discs | Low maintenance, any disc wear automatically compensated by piston travel | Remote control capability | Continuous increase of oil pressure, and so shockless switching | Mechanical emergency operation device on failure of hydraulic oil supply |

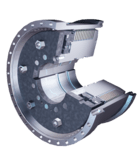

Synchro sye 270 multi plate clutch from GKN Stromag

Synchronisation unit for industrial gears | Suitable for rated torques up to 27,000 Nm and speeds up to 3000 rpm | Short-time admissible max torque up to 45,000 Nm | - Also torque peaks can be absorbed reliably by the pretensioned gears. | High heat capacity of the discs compared with conical systems | - Reliable synchronisation of high inertias and drag torques | Precise guidance of the sliding sleeve on the hub | - No jamming of the sliding sleeve for reliable switching processes | Large gear overlap between sliding sleeve , speed hub, and hub | - Reliable transmission of high torques (design patent application submitted) |