Description

Dynamic Braking Units and Resistors

Magnetek’s Dynamic Braking Resistors

Magnetek’s Dynamic Braking Resistors are designed specifically for crane and hoist duty cycles. Working in concert with our Dynamic Braking Units, Magnetek’s Dynamic Braking Resistors dissipate energy generated from motors controlled byIMPULSE® brand variable frequency drives. Our Drives can be referenced to your crane’s CMAA duty cycle.

We offer our Standard Dynamic Braking Resistors or our new cULus certified Dynamic Braking Resistors. All our resistors are:

- Built with rigid galvanized steel or stainless steel enclosures

- Suitable for a variety of applications or may be customized to meet the needs of specific applications

Standard Dynamic Braking Resistor Option

- Available in smooth wound, wire wound or edge wound resistor coils

- Grid type resistors available for the most volatile applications

- Weatherproof louvered enclosure option

- Designed to meet UL508A and CSA C22.2 No. 14 safety standards

- Available in: grid, wire wound or edge wound resistor coils

- Mounted in hooded, ventilated enclosures

Pair Magnetek’s cULus certified resistors with our cULus certified control panels to provide a complete motor control solution that meets industry safety standards.

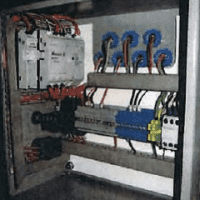

CDBR-D Dynamic Braking Units

The full line of CDBR-D Dynamic Braking Units is now available. The new units reduce enclosure and panel costs and increase catwalk space on cranes with advanced features including:

- Short circuit protection with an independent fault output

- Up to a 40% smaller footprint than previous generation CDBR-B units

- Additional diagnostic LEDs

- 60°C ambient operating temperature rating

- Additional voltage threshold settings available