Description

Ringspann Brakes

Spring Applied, Pneumatically Released

-

-

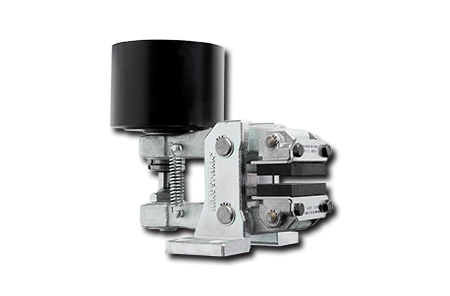

DH 010 FPM

spring activated – pneumatically releasedFeatures Code Brake Caliper D Mounting to the machine at right angles to the brake disc H Frame size 010 010 Spring activated F Pneumatically released P Manual adjustment to accommodate friction block wear M Pressure piston 010 or 012 are available for selection 010

012Pressure piston mounted in central position M Thickness of brake disc 12,5 mm 12

-

-

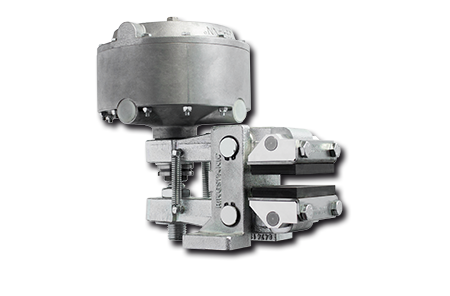

DV 020 FPM

spring activated – pneumatically releasedFeatures Code Brake Caliper D Mounting to the machine parallel to the brake disc V Frame size 020 020 Spring activated F Pneumatically released P Manual adjustment to accommodate friction block wear M Pressure piston 020, 030 or 040 are available for selection 020

030

040Thruster mounted right or left available R

LThickness of brake disc 12,5 mm 12

Installation instruction DV-DH 020 FPM

-

-

DH 020 FPM

spring activated – pneumatically releasedFeatures Code Brake Caliper D Mounting to the machine at right angles to the brake disc H Frame size 020 020 Spring activated F Pneumatically released P Manual adjustment to accommodate friction block wear M Pressure piston 020, 030 or 040 are available for selection 020

030

040Position of the thruster to the right or left can be determined by turning the brake during installation U Thickness of brake disc 12,5 mm 12

-

DH 025 FPA

spring activated – pneumatically releasedFeatures Code Brake Caliper D Mounting to the machine at right angles to the brake disc H Frame size 025 025 Spring activated F Pneumatically released P Automatic adjustment to counter friction block wear A Pressure piston 065, 085 or 095 are available for selection 065

085

095Thruster mounted right or left available R

LThickness of brake disc 12,5 mm or 25 mm 12

25-

-

DV 030 FPM

spring activated – pneumatically releasedFeatures Code Brake Caliper D Mounting to the machine parallel to the brake disc V Frame size 030 030 Spring activated F Pneumatically released P Manual adjustment to accommodate friction block wear M Pressure piston 025, 035, 045 or 101 are available for selection 025

to

101Thruster mounted right or left available R

LThickness of brake disc 12,5 mm or 25 mm 12

25 - Installation instruction DV/DH 025/030/035 FPM

-

-

-

DV 035 FPM

spring activated – pneumatically releasedFeatures Code Brake Caliper D Mounting to the machine parallel to the brake disc V Frame size 035 035 Spring activated F Pneumatically released P Manual adjustment to accommodate friction block wear M Pressure piston 102, 111 or 122 are available for selection 102

111

122Thruster mounted right available R Thickness of brake disc 12,5 mm, 25 mm, 30 mm or 40 mm 12

25

30

40Spring-Applied, Hydraulically Release Brake Calipers

-

-

HS 075 FHM

spring activated – hydraulically releasedFeatures Code Brake Caliper H Floating caliper S With piston diameter 75 mm 075 Spring activated F Hydraulically released H Manual adjustment to accommodate friction block wear M Spring packages available for clamping forces of 10 kN, 20 kN, 30 kN, 40 kN or 55 kN -

-

HS 120 FHM

spring activated – hydraulically releasedFeatures Code Brake Caliper H Floating caliper S With piston diameter 120 mm 120 Spring activated F Hydraulically released H Manual adjustment to accommodate friction block wear M Spring packages available for clamping forces of 30 kN, 50 kN, 70 kN, 100 kN or 120 kN 030

to

120-

-

Features Code Brake Caliper H Standard W With piston diameter 2 x 75 mm 150 Hydraulically activated H Non-releasing U No adjustment to counter friction block wear K Max. clamping force 140 kN 140 -

-

HW 120 FHM

spring activated – hydraulically releasedFeatures Code Brake Caliper H Standard W With piston diameter 120 mm 120 Spring activated F Hydraulically released H Manual adjustment to accommodate friction block wear M Spring packages available for clamping forces of 30 kN, 50 kN, 70 kN, 100 kN or 120 kN 030

to

120-

-

HW 150 HUK

hydraulically activated – non-releasingFeatures Code Brake Caliper H Standard W With piston diameter 2 x 75 mm 150 Hydraulically activated H Non-releasing U No adjustment to counter friction block wear K Max. clamping force 140 kN 140 HW 150 HUK

hydraulically activated – non-releasing

-

-

-

-

HI 150 HUK

hydraulically activated – non-releasingFeatures Code Brake Caliper H With inside-mounted brake pads I With piston diameter 2 x 75 mm 150 Hydraulically activated H Non-releasing U No adjustment to counter friction block wear K Max. clamping force 140 kN 140 -

-

HS 075 FHM

spring activated – hydraulically releasedFeatures Code Brake Caliper H Floating caliper S With piston diameter 75 mm 075 Spring activated F Hydraulically released H Manual adjustment to accommodate friction block wear M Spring packages available for clamping forces of 10 kN, 20 kN, 30 kN, 40 kN or 55 kN 010

to

055-

-

HS 075 HFK

hydraulically activated – spring releasedFeatures Code Brake Caliper H Floating caliper S With piston diameter 75 mm 075 Hydraulically activated H Spring released F No adjustment to counter friction block wear K Max. clamping force 55 kN 055

-

-

HW 075 FHM

spring activated – hydraulically releasedFeatures Code Brake Caliper H Standard W With piston diameter 75 mm 075 Spring activated F Hydraulically released H Manual adjustment to accommodate friction block wear M Spring packages available for clamping forces of 10 kN, 20 kN, 30 kN, 40 kN or 55 kN 010

to

055KEFH

-

-

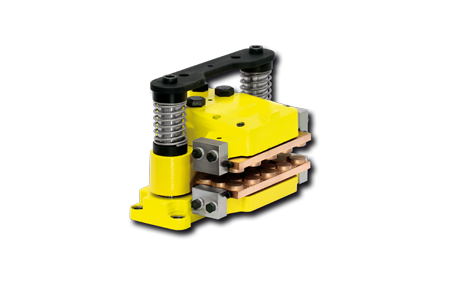

KEFH

spring activated – hydraulically or pneumatically released

hydraulically releasedFeatures

- For continuous piston rod clamping

- Spring activated, hydraulically released

- Holding forces transmissible in both directions of movement

- No application of force (lifting) to the piston rod required for release

- Datasheet KEFH

KEFP

-

-

KEFP

spring activated – hydraulically or pneumatically released

pneumatically releasedFeatures

- For continuous piston rod clamping

- Spring activated, pneumatically released

- Connection dimensions compatible with pneumatic cylinders according to ISO

- Direct mounting on pneumatic cylinders

- Holding forces transmissible in both directions of movement

- No application of force (lifting) to the piston rod required for release

-

BCS 600

-

-

BCS 600

for controlled braking

continuous monitoringFeatures

- Fast reduction of the gap between disc and brake pad

- Continuous monitoring of rotational speed, hydraulic pressure, oil temperature and rotational direction

- Operation as a stand alone braking system is possible

- Periodically light braking to clean the brake disc

- Graphical visualization of the braking process in real time

- Redundant installation of a second braking system is possible (one supports the other if necessary)

- Retrofit or upgrade of outdated braking systems is possible

- Permanent logging of operating data and system events

- Spring pressure monitoring

Hydraulic Power Unit

-

-

Hydraulic Power Unit

Other- Compact design because of the cylindrical dimensions of the tank

- Optimized oil-connection of pressure side provided by two connection arranged at 90°

- Easy mounting because of two mounting possibilities; therefore, no complex mounting frames are required

- Inside and outside of the tank is oil-resistent powder-coated

Hydraulic Power Units can be made according to customers demand.

Installation instruction Hydraulic Power Unit

-

-

-

-

-

-

-

-