Description

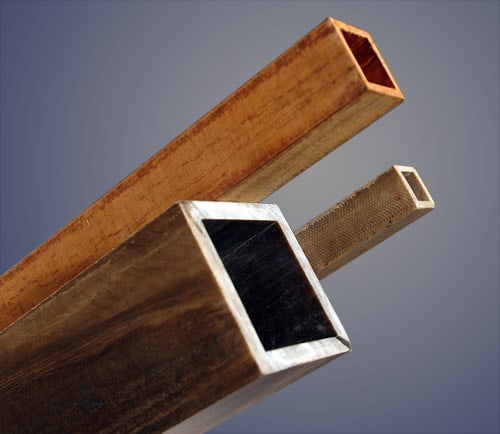

Lamitex® Compression Molded Angles, Channel, Rods and Square & Rectangular Tubes

- Mold laminated products are available in most Nema Grade laminates.

- Epoxy and Phenolic rectangular tubes are molded every day.

- Molded rods in most Nema grades are available from .250″- 4.00″ in diameter. Lengths vary from 34″-40″ long.

- Linen/canvas and epoxy molded rod provides better strength for machined parts when compared to rod ground from sheet stock.

- Molded angle and channel from G-9, G-10 and G-11 provides better mechanical strength, electrical properties and temperature resistance than glass polyester angle and channel.

- Profiles and tubes processed on high pressure presses ensure that the mechanical strength of the shapes will be close to that of pressed sheet grades.

- Large inventory of steel tooling and press production capacity guarantees quoted delivery.

Roll over the image below to see a larger view

Expert in Lamitex and other Phenolic Laminates

ndustrial Laminates

Industrial Laminates:

- Lamitex® thermoset high-pressure laminate grades in Sheet, Rod and Tube in stock.

- All NEMA grades available, Phenolic, Epoxy, Melamine, Silicone and specialty grades.

- Common Grades include, X, XX, C, CE, LE, G-3, G-5, G-7, G-9, G10, FR-4 and G-11.

- Laminate Insulation is readily machined to customer specifications.

- Custom specialty grades include Kevlar® filled Phenolic and Fiberglass/Polyimide high-temperature laminates.

- Laminate sheet and laminated tubing with graphite filler for high wear mechanical applications.

- Filament wound fiberglass epoxy tubes.

- Large inventory of laminated tube stock, including heavy walled tubing.

Kor-Pak is skilled at manufacturing, fabricating and distributing industrial high-pressure laminates. Lamitex® composite materials are engineering materials made from fibrous reinforcement such as cotton cloth, paper or woven fiberglass cloth, which are bonded together with high quality plastic resins. The layers are pressed together under high-pressure and the resin is baked until it becomes solid, fusing the material into a tough, strong composite. Combining different resins, – such as phenolic, epoxy, melamine or silicone – with different types of reinforcement creates a full range of Lamitex® grades to suit a wide variety of applications. Lamitex® high-pressure laminates combine mechanical strength and electrical insulation with chemical and weather resistance. They’re rigid with high strength – to – weight ratio and can be machined to very close tolerances.